Complex Tube & Hose Assemblies | Parker Stratoflex

As aerospace hydraulic and engine system designs become more compact and complicated, unique and versatile fluid-conveyance solutions are necessary. Parker Stratoflex complex metal tube and flexible hose assemblies provide hybrid component combinations customized to fit any build envelope or design. Available in a variety of material options and pressure/temperature combinations, Stratoflex’s metal tube and flexible hose assemblies offer design flexibility with reduced weight and metal fatigue compared to standard all-metal tubing.

Popular with engine manufacturers and aircraft service technicians, Stratoflex metal tube and flexible hose assemblies are designed for ease of maintenance and serviceability to keep aircraft in the air and out of the hangar. With decades of engineering design and testing experience at our fingertips, and one of the largest on-site engineering teams in the industry, Parker Stratoflex can give your fluid conveyance system a custom competitive edge. From custom components to fully integrated systems, our engineering resources are available to design and create the perfect solution for your aerospace needs.

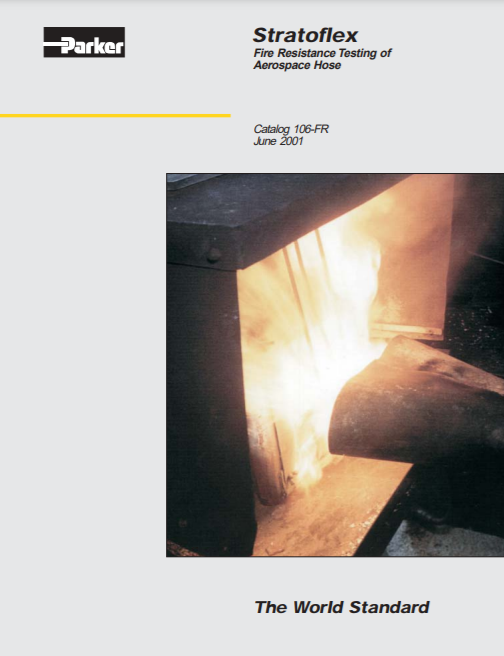

Parker Stratoflex has one of only a few FAA qualified fire test labs in the United States, giving our engineers unparalleled access and flexibility to design and fully fire test our products to the most stringent customer and regulatory requirements. Stratoflex metal tube and flexible hose assemblies are available with both slip-over and integral firesleeves. The integral firesleeve is designed with smaller envelope dimensions than conventional slip-over sleeves for greater versatility in tight spaces, and offers superior vibration dampening compared to non-integral products. Wicking and contamination are prevented as the hose is completely contained within the firesleeve.

Pressure

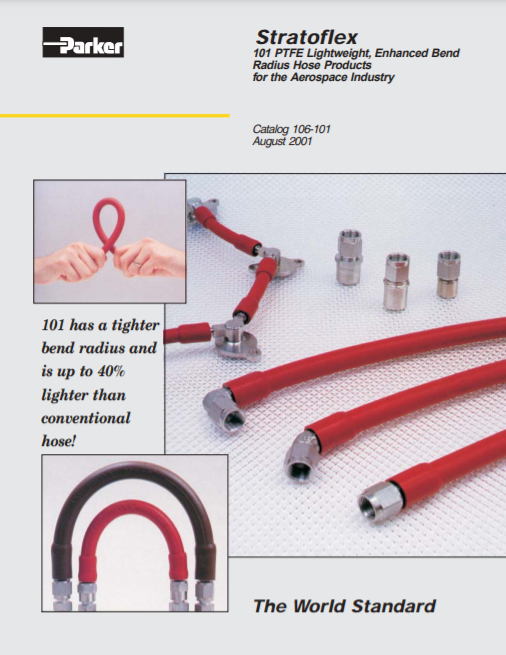

• Low Pressure Assemblies101 Series low pressure fuel / oil hose assemblies with firesleeve jacketing

3162 Series convoluted low pressure hose assemblies

3192 Series lightweight low pressure hose assemblies

• Medium Pressure Assemblies

124 Series medium pressure hose assemblies

3175 Series highly flexibly medium pressure hose assemblies

• High Pressure

171 Series high pressure hydraulic hose assemblies

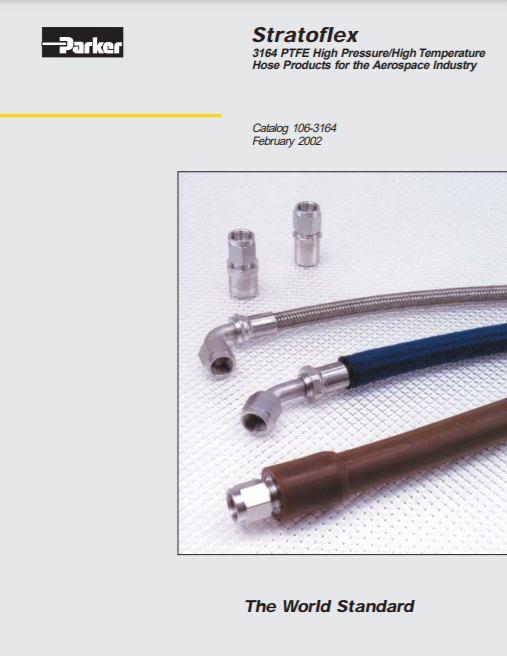

3164 Series high pressure hose assemblies – 4000 PSI max operating pressure

3154 Series high pressure para aramid hose assemblies

191 Series high pressure hydraulic hose with Cordura covering

158 Series high pressure hydraulic hose – 5080 PSI max operating pressure

• Heavyweight Assemblies

170 Series hydraulic high pressure heavyweight hose assemblies

Feature & Attributes

• Reduced weight• Reduced metallic fatigue

• Reduced vibration

• Ease of maintenance

• Customized design to fit any build envelope

Optional Features

- Stratoflex metal tube and flexible hose assemblies are available in many configurations to suit your needs.

• Working pressures up to 5,080 psi

• Available with integral and slip-over fire sleeves

• Material options including:

o Aluminum

o CRES (multiple variations available)

o Titanium (multiple variations available)

o Nickel alloys (such as INCO 625, INCO 718, etc.)

Tech Specifications

MAXIMUM OPERATING PRESSURE: 5,080 psi

MATERIALS OF CONSTRUCTION: Aluminum, CRES, titanium, or nickel alloys

Print Tech Specifications

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise. The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors. To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.

Parker Stratoflex Catalogs & Literature