Table of Contents

It is surprising to see how many people still prefer analog meters over digital ones. It is true that digital meters can be much more expensive and complex than their analog counterparts but if you consider all their advantages, the digital meters clearly come out as a better choice for any professional.

It is surprising to see how many people still prefer analog meters over digital ones. It is true that digital meters can be much more expensive and complex than their analog counterparts but if you consider all their advantages, the digital meters clearly come out as a better choice for any professional.

Both analog and digital meters are capable of measuring a wide variety of quantities. Depending on a meter's specific design, it can measure electricity, energy, force or volume. Simple meters are composed of a numbered display and a physical needle or pointer that moves across the display in accordance with the amount of energy applied to it. Meters of this type are termed analog meters. Digital meters display the same types of measurements with an electronic display instead of a pointer over a scale.

Digital meters are more accurate

With an analog meter, slight changes in the needle's position relative to the numbered display behind it can make its readout inaccurate and difficult and any fractional readings can only be guessed at. Exact numbers are impossible to measure with an analog meter.

With an analog meter, slight changes in the needle's position relative to the numbered display behind it can make its readout inaccurate and difficult and any fractional readings can only be guessed at. Exact numbers are impossible to measure with an analog meter.

Also, most analog meters show multiple scales for reading different quantities on their displays. This is another source of errors - users can read the wrong scale.

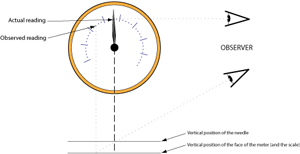

Parallax

Another disadvantage of analog meters is that you must look directly at the dial of an analog meter in order to read its display accurately. If you look at it at an angle, you get an inaccurate reading. A digital meter simply displays a number and is immune to this error (known as parallax).

Another disadvantage of analog meters is that you must look directly at the dial of an analog meter in order to read its display accurately. If you look at it at an angle, you get an inaccurate reading. A digital meter simply displays a number and is immune to this error (known as parallax).

One of the most important advantages of the digital meters is their ability to detect pressure spikes. With analog equipment, pressure spikes may move a needle slightly but will not give an accurate reading of the maximum pressure.

Digital meters can take measurements in intervals as short as a few milliseconds so they catch even very short spikes in pressure.

No need to set the scale with digital meters

Before taking a measurement with your analog meter, you have to take an educated guess at a range of values you expect to see - and set the scale. What if you are wrong? If you misjudge the scale, the reading will be too high or too low to read. In some cases, you can damage the meter. So if you do not know what values to expect, you have to start with the highest scale and work your way down until you hit the correct range.

Most digital meters have circuitry that automatically detects the scale and indicates it on the display making them easier and quicker to use than analog meters.

Portability creates a need for durability

Digital meters use circuitry to measure quantities so they can be nearly any practical size. This feature makes them potentially more portable than their analog counterparts, which are limited in scale by their need to house mechanical components.

Digital meters use circuitry to measure quantities so they can be nearly any practical size. This feature makes them potentially more portable than their analog counterparts, which are limited in scale by their need to house mechanical components.

Increased portability necessitates increased durability. Because digital meters contain fewer or no exposed moving parts, there is less danger of damage, which could lead to inaccurate readings. An analog meter is more likely to suffer damage to its moving parts.

Push-button calibration

Analog meters are calibrated mechanically. Over time, the process of calibrating an analog meter can stress its moving parts, moving them too far from their original positions relative to each other to provide accurate readings.

Analog meters are calibrated mechanically. Over time, the process of calibrating an analog meter can stress its moving parts, moving them too far from their original positions relative to each other to provide accurate readings.

A digital meter is calibrated by exposing it to a neutral, or zero-level, signal and then setting the readout to zero. This is typically accomplished with the push of a button, which sends a signal to the meter to reset the readout.

Surge Protection

Electronics-related digital meters have built-in overload protection that is uncommon in analog meters. The components of an analog meter will burn out if exposed to too strong of an electrical load. A digital meter is protected from the same load.

See a related blog on how to select a digital meter for your needs. For more tips on hydraulic and pneumatic systems, visit our technical pages or browse through our past blogs.

Posted by Joni Scott