Table of Contents

|

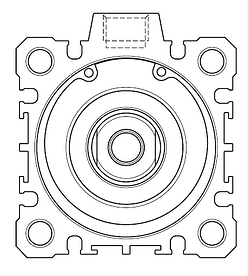

The new P1Q design incorporates flush mount sensor grooves on multiple sides of the cylinder body. The new flush mount design will maximize sensor protection, while allowing access to multiple sides of the cylinder. In addition, a few dimensional changes have been incorporated on bore sizes 12 mm through 20 mm. Please download the updated Parker Catalog 0960-E for more information. |

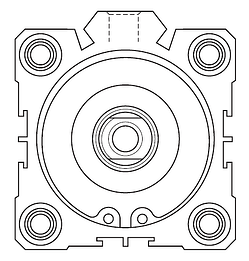

Old Profile |

Updated Profile |

|

|

Electronic Sensor Part numbers have also changed – please see the cross reference table below:

Sensors Cross-Reference to Replacement Part Numbers

Obsolete Part Number |

Replacement Part Number |

|

P8S-CPSHS |

P8S-EPSUS |

|

P8S-CPMHS |

N/A - M12 no longer available due to low demand |

|

P8S-CPFLS |

P8S-EPFXS |

|

P8S-CNSHS |

P8S-ENSUS |

|

P8S-CNMHS |

N/A - M12 no longer available due to low demand |

|

P8S-CNFLS |

P8S-ENFXS |

|

P8S-CRSHS |

P8S-ERSUSP8S-ERSUS |

|

P8S-CRMHS |

N/A - M12 no longer available due to low demand |

|

P8S-CRFLS |

P8S-ERFXS |

|

P8S-CPSHR |

P8S-EPSUS |

|

P8S-CPMHR |

N/A - M12 no longer available due to low demand |

|

P8S-CPFLR |

P8S-EPFXS |

|

P8S-CNSHR |

P8S-ENSUS |

|

P8S-CNMHR |

N/A - M12 no longer available due to low demand |

|

P8S-CNFLR |

P8S-ENFXS |

|

P8S-CRSHR |

P8S-ERSUS |

|

P8S-CRMHR |

N/A - M12 no longer available due to low demand |

|

P8S-CRFLR |

P8S-ERFXS |

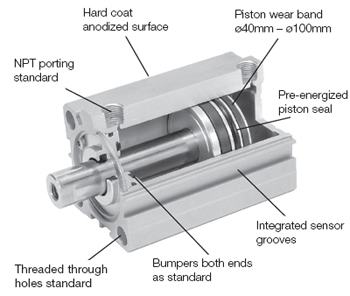

P1Q: Great Cylinder For Small Spaces

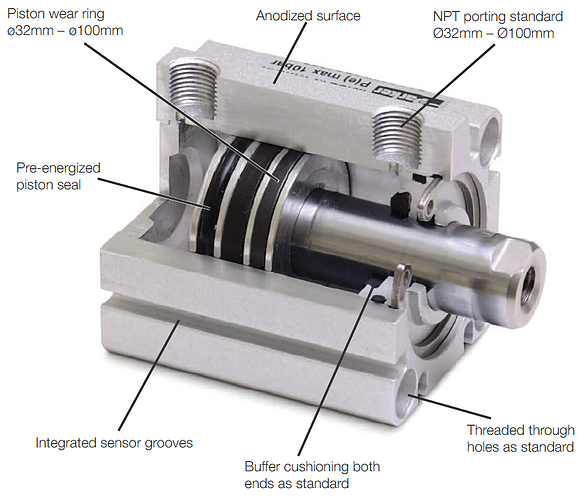

- Built-in bumpers result in quieter operation.

- Standard stroke ranges of 5 mm to 100 mm (0.2” to 4”).

- 10 standard bore sizes range from 12 mm to 100 mm (0.5” to 4”).

- Working pressure up to 145 psi.

- Piston wear bands increase service life (available for bore sizes 40 mm to 100 mm).

- Rod end thread options may be either female or male.

- Rod ends may be either magnetic or non-magnetic.

- Teflon piston wear ring (available with magnetic option, 32 – 100 mm bores) provides increased service life.

Parker Pneumatic Division also released a new Cross Reference Tool for the P1D Series ISO Cylinders. Easily convert competitive part numbers to a Parker ISO Cylinder equivalent with just a few clicks.

Posted by Roger Winchell

![Parker P1D Cylinders Improve Pneumatic System Safety [During Power Outage]](http://www.mfcp.com/hs-fs/hubfs/images/product/Pneumatic-Actuator-Products/Tie-Rod-Pneumatic-Cylinders/parker-P1D-series-rod-lock.png?width=400&name=parker-P1D-series-rod-lock.png)