Air Savers | Common Applications

What is an Air Saver?

|

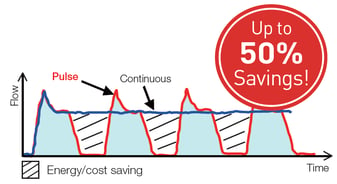

A valve that converts constant flow of air to pulsing air (Pulsing Air Valve), reducing compressed air consumption In open-ended pneumatic applications, compressed air consumption can be reduced by up to 50%, while performing the same amount of work.

|

What Others Say about Air Savers FAQs Overview Selection Table

FOR HELP WITH USING AIR SAVERS

|

Application Examples

- Demo: Difference between steady flow and Air Saver pulsing flow - Agitation

- PET bottles blow molding

- Automotive - Machining Application

- Automotive - Parts Cleaning Application

- Plastic Parts Manufacturing - Parts Feeder Application

Common Applications

|

Cooling Applications | |

|

Painting Process | Automotive spray painting Industrial spraying of components |

|

Cleaning Applications |

Swarf Removal Cleaning blow before assembly |

|

Drying Applications | Liquid removal after the manufacturing process |

|

Ionizer Dust Removal | Semiconductor manufacturing |

|

Assembly line assist blow | Assist blow for PET bottle transfer |

Air Savers can reduce compressed air consumption in almost any open ended (non-actuating) pneumatic application. If a blow of air is being used to move parts, clean parts, dry parts, or to agitate, chances are that Air Savers can save you money. Contact our Engineering Department with questions about your particular application.