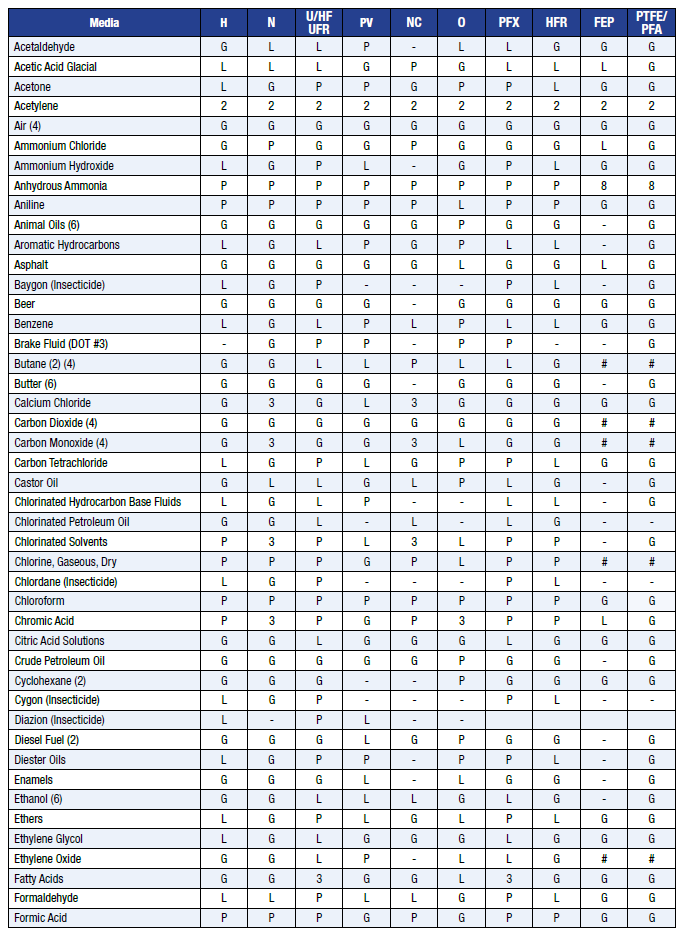

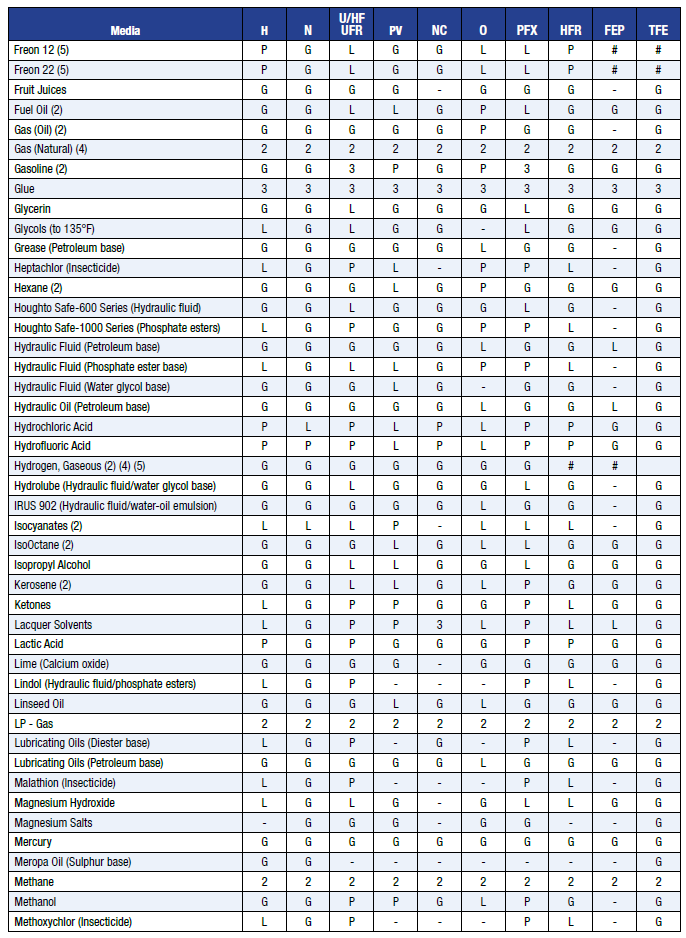

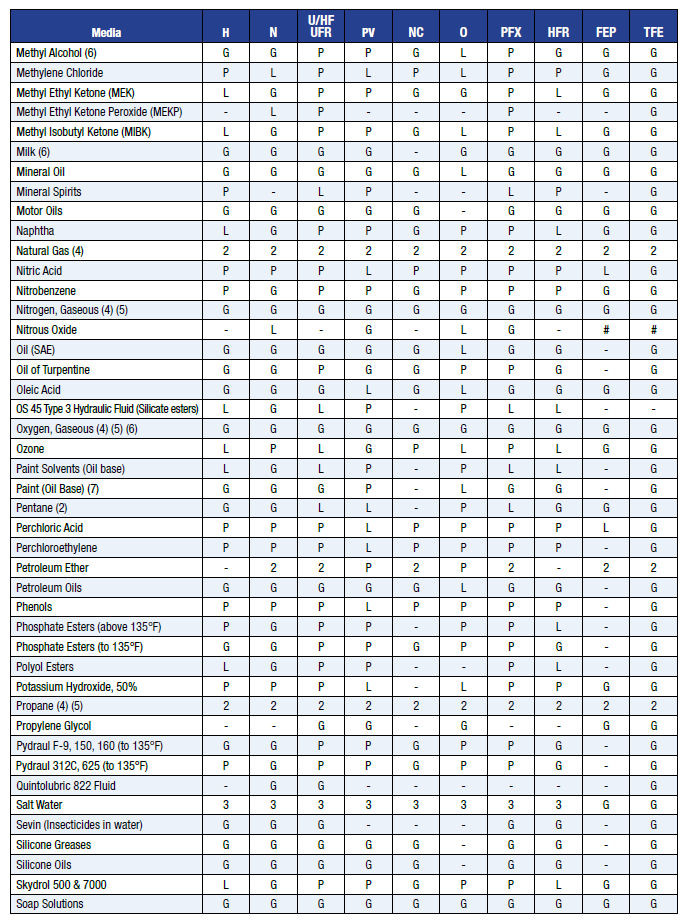

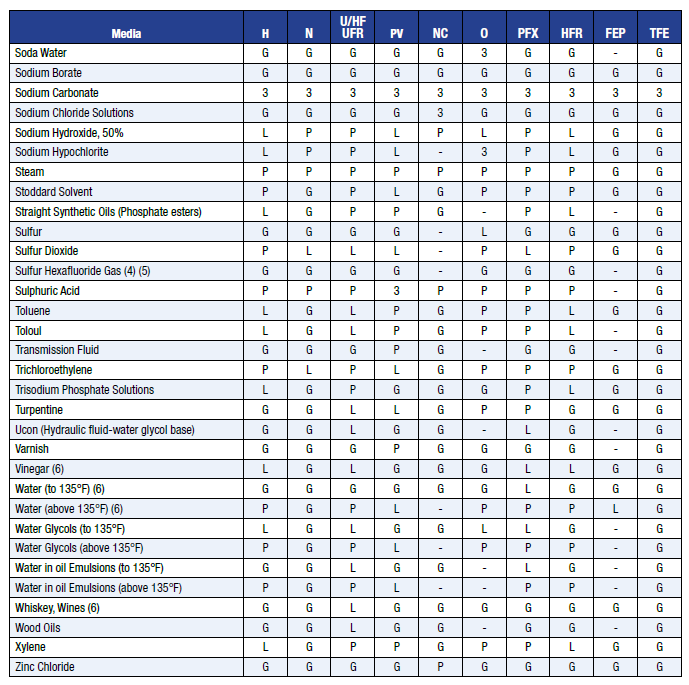

The information below covers the chemical compatibility of Parker hoses, which are listed in Parker Parflex Catalog 4660, Edition 8/2014 (Thermoplastic & Fluoropolymer Products). This chemical compatibility guide must not be used in conjunction with any other compatibility guides from previous or future catalog editions, bulletins or publications. Incorrect use of these charts could result in personal injury, death or property damage.

| Parker Thermoplastic Hose | Core Material | Code |

| D6, D6R, H6, R6, HFS, HFS2, HFSR, M8, HTB, HJK, 560, 563, 590, 593, 510C, 518C, 515H, 53DM/538DM, 55LT, HLB, S5N, S6, S9, SLH | Copolyester | H |

| 510D, 518D, 520N, 526BA, 527BA, 528N, 540N, 548N, 56DH/568DH, 573X, 575X, 580N, H580N, 588N, 1035HT, 5CNG, MSH, PTH | Nylon | N |

| 510, 510A | Nylon Copolymer | NC |

| 540P | Copolymer | O |

| 1035A | Proprietary Elastomer | PFX |

| 919/919B, 919J, 919U, 929/929B, 929BJ, 939/939B, 943B, 944B, 950B, 955B, S30/S30B, S40/S40B, STW/STWB, SCW/SCB, PCW/PCB, SBFB/SBFW, SCWV/SCBV, PCWV/PCBV, SCWV-FS/SCBV-FS, PCWV-FS/PCBV-FS | Fluoropolymer PTFE/PFA | TFE/PFA |

| 83FR, B9 | Polyurethane | U |

| Parker Thermoplastic Hose | Cover Material | Code |

| RCTW/RCTB (Contact Engineering for chemical resistance questions) | Rubber | EPDM |

| 55LT, 53DM/538DM | Low Temperature Copolyester | HF |

| 510C, 518C | Proprietary Elastomer | PFX |

| SWPV, 919J, 929BJ | Silicone | M |

| All except 55LT, 53DM/538DM, 518C, 1035HT and PTFE hoses | Polyurethane | U |

| G | Good to Excellent - Little or no swelling, tensile or surface changes. Preferred choice. |

| L | Marginal or Conditional - Noticeable effects but not necessarily indicating a lack of serviceability. Further testing suggested for specific applications. Long-term effects such as stiffening or potential for crazing should be evaluated. |

| P | Poor or Unsatisfactory - Not recommended without extensive and realistic testing. |

| - | Not tested - Compatibility not known. |

| # | For fluoroplolymer - Indicates good chemical resistance but potential for excessive permeation. |

Warning: Cancer or Reproductive Harm

@Copyright 2020 MFCP. All rights reserved.