Air Savers | Pulsing Air Technology for Drying and Blow Applications

If reducing compressed air consumption is your objective, you are in the right place.

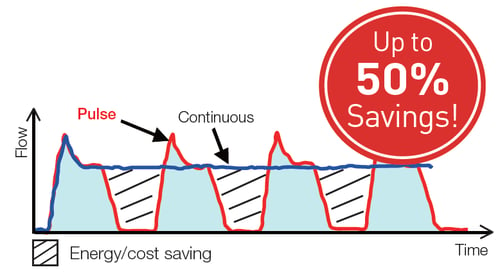

An Air Saver is a valve that converts a continuous air blow to a pulsed air blow without the need for any other external control. Air is blown with a series of ON and OFF pulses. When the blow is OFF, there is no air consumption.

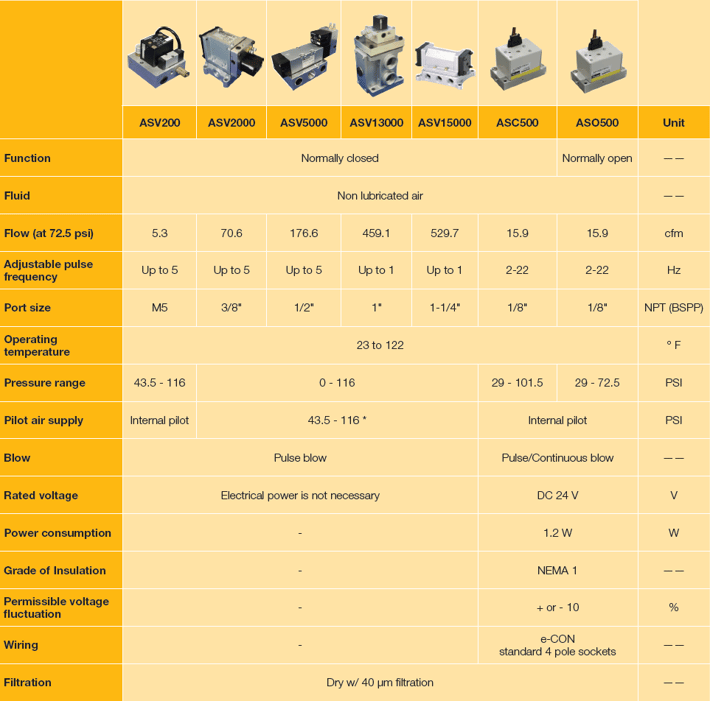

- Air Saver (Pulsating Air Valve) Selection Guide

- Air Saver Applications

- Technical Questions about Air Savers in Your Specific Application

- FAQ

- Download a Free PDF Catalog (5.4 MB)

- VIDEO: How Do Air Savers Work?

- VIDEO: Test - pulsing air versus continuous flow in agitating application

Pulsing Air Technology Reduces Energy Consumption by up to 50%

|

Pulsing air technology is the answer for reducing compressed air consumption in blowing/open-end (non-actuating) applications, which include drying, cleaning, blow guns, agitators and other uses. Pulsing air valves can be effective in many applications where air blow is a requirement, such as PET bottle transfer, painting process, swarf removal, cooling applications, and ionizer dust removal.

Installation is simple and the reduction in air consumption can be realized immediately and the investment is typically recovered within the first year of use.

When using an electrically operated solenoid valve to control the air blow, the pulsating air valve can be quickly retrofitted.

Choosing a Correct Air Saver for Your Application

To choose the correct pulsating air valve, you will need the following specifications:

- System operating pressure (PSI)

- Port size

- Required flow (cfm) for nozzle(s) controlled by a single valve.

- Availability of a DC 24V power source (pilot operated valves available if not)

Once you gather the information, consult the Air Saver Selection Guide.

Pulsating Air Valves Comparison

Note: External pilot of 43.5 to 116 PSI is required to ensure proper operation.