Parker Series 3HD Cylinders

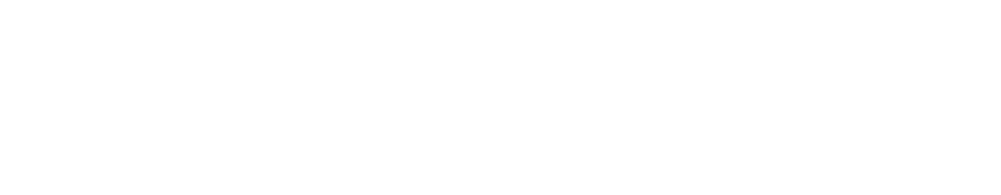

Series 2HD Design Improvements Increase Reliability

A) Primary Seal – Polyurethane Tri-Lip Rod Seal is a proven leak proof design – completely self-compensating and self-relieving to withstand variations and conform to mechanical deflection that may occur. Alternative seal materials are

available to suit your application.

B) Secondary Seal – Polyurethane Rod Wiper –wipes clean any oil film adhering to the rod on the extend stroke and cleans the rod on the return stroke.

C) Rod Gland Assembly – Bronze gland is externally removable without cylinder disassembly. Long inboard bearing surface is ahead of the seals assuring lubrication by cylinder operating fluid.

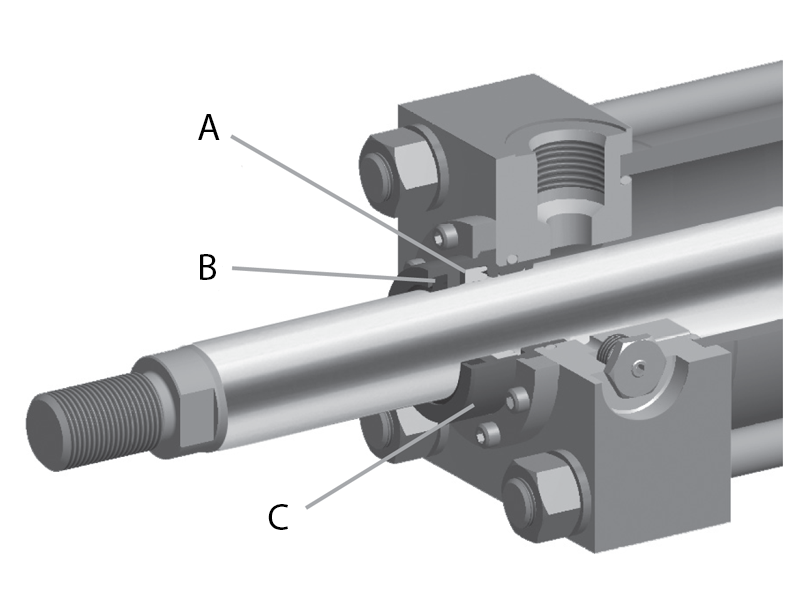

Parker Crown Wiper™ for Series 2HD 1.50" - 6.00" and 7.00" & 8.00" bore 3HD

For environments that contain fine abrasive particulate specify the Crown Wiper option. The Crown Wiper is a proven superior alternative to piston rod end boots or metallic wipers that can ingest particulate. It has a sharp leading edge to effectively clean the piston rod and a beveled shape to prevent contaminant intrusion by channeling it away from the gland. It also acts as a secondary seal to wipe clean any oil film adhering to the rod on the extend stroke.

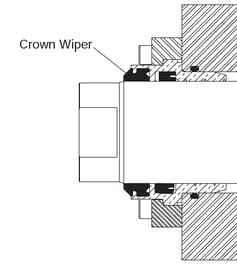

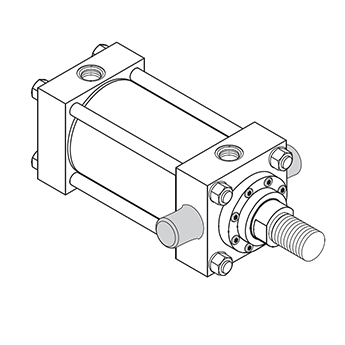

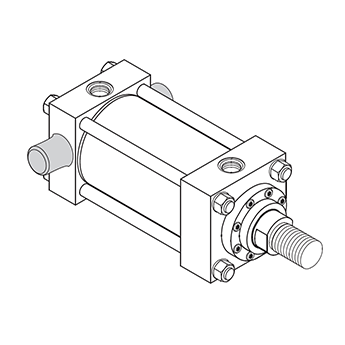

Parker Series 3HD Heavy Duty Hydraulic Cylinder

Series 2HD 1.50"-6.00" and 3HD 7.00" & 8.00" Bore cylinders offer increased durability and ease of service with the addition of a bolt-on rod gland. The gland assembly is externally removeable without cylinder disassembly. The rod seal has multiple sealing edges to produce "dry rod" performance and it is molded from a special polyurethane material that is extremely resistant to abrasion and extrusion.

Standard Specifications

- Heavy Duty Service – ANSI/(NFPA) T3.6.7R3 - 2009

- Specifications and Mounting Dimension Standards

- Standard Construction – Square Head – Tie Rod Design

- Nominal Pressure – 3000 psi1

- Standard Fluid – Hydraulic Oil

- Standard Temperature – -10°F to +165°F2

- Bore Diameters – 7.00" & 8.00" (Larger sizes available)

- Piston Rod Diameter – 0.625" through 5.500"

- Mounting Styles – 19 standard styles at various application ratings

- Strokes – Available in any practical stroke length

- Cushions – Optional at either end or both ends of stroke. “Float Check” standard at cap end of 1.50" - 6.00" bore.

- Rod Ends – Four Standard Choices – Specials to Order

1 If hydraulic operating pressure exceeds 3000 psi, send application data for engineering evaluation and recommendation. See Section H for actual design factors.

2 See Section H for higher temperature service.

Note: Series 2HD and 3HD Hydraulic Cylinders fully meet ANSI/(NFPA) T3.6.7R3 - 2009 Specifications and Mounting Dimension Standards for Square Head Industrial Fluid Power Cylinders.

In line with Parker's policy of continuing product improvement, specifications on this page are subject to change.

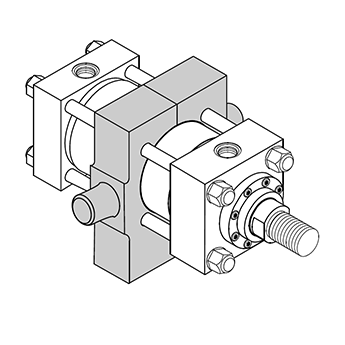

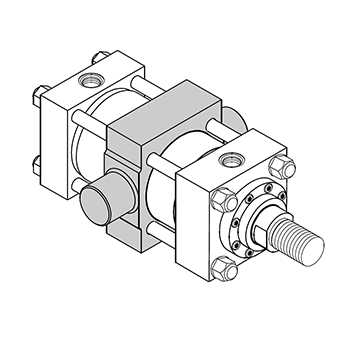

Available Mounting Styles

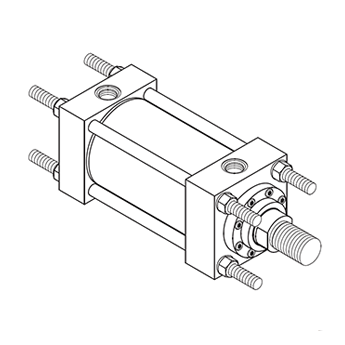

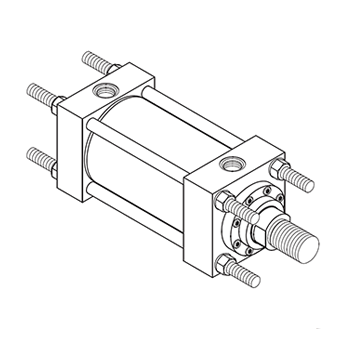

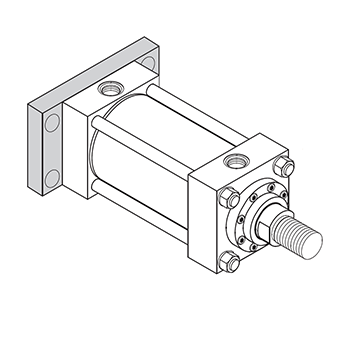

- Tie Rods Extended Head End

- NFPA MX3

- 7.00" - 8.00"

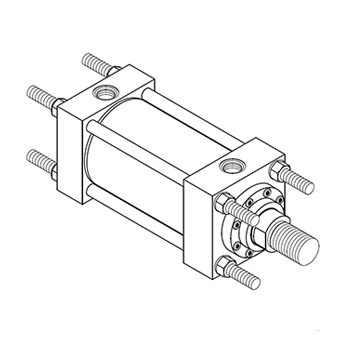

- Tie Rods Extended Cap End

- NFPA MX2

- 7.00" - 8.00"

- Tie Rods Extended Both Ends

- NFPA MX1

- 7.00" - 8.00"

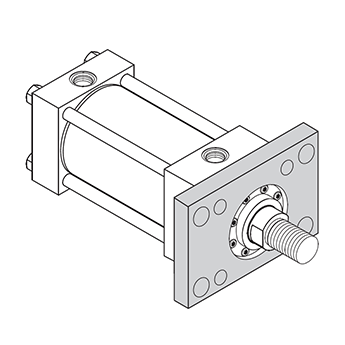

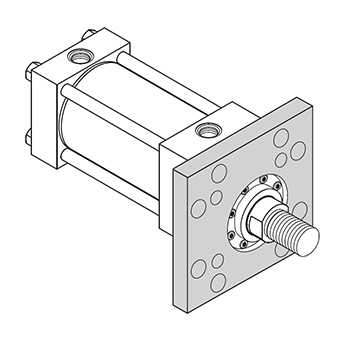

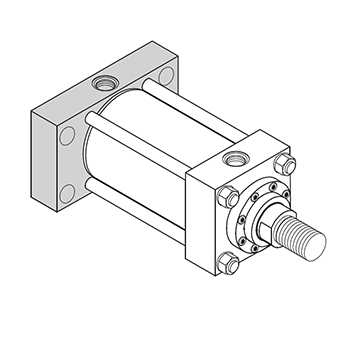

- Head Rectangular Flange

- NFPA MF1

- 7.00" - 8.00"

- Head Square Flange

- NFPA MF5

- 7.00" - 8.00"

- Head Rectangular

- NFPA ME5

- 7.00" - 8.00"

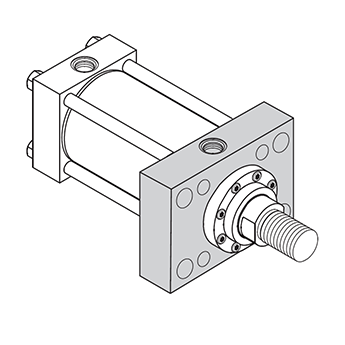

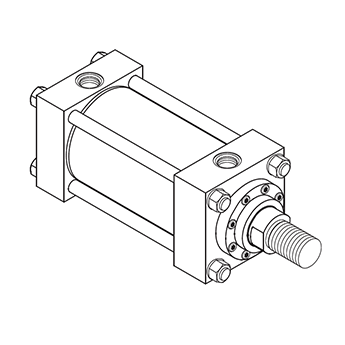

- Cap Rectangular Flange

- NFPA MF2

- 7.00" - 8.00"

- Cap Square Flange

- NFPA MF6

- 7.00" - 8.00"

- Cap Rectangular

- NFPA ME6

- 7.00" - 8.00"

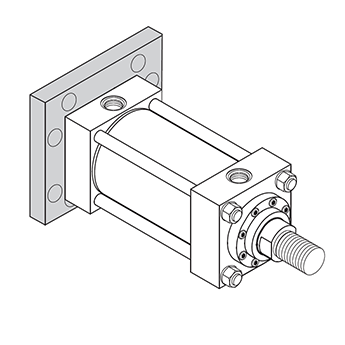

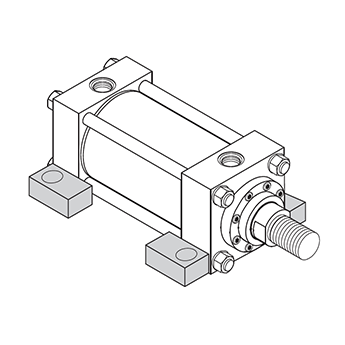

- Side Lug

- NFPA MS2

- 7.00" - 8.00"

- Side Tapped

- NFPA MS4

- 7.00" - 8.00"

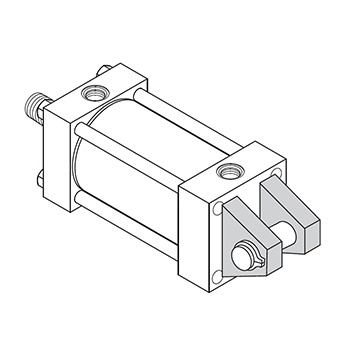

- Cap Fixed Clevis

- NFPA MP1

- 7.00" - 8.00"

- Head Trunnion

- NFPA MT1

- 7.00" - 8.00"

- Cap Trunnion

- NFPA MT2

- 7.00" - 8.00"

- Intermediate Fixed Trunnion

- NFPA MT4

- 7.00" - 8.00"

- HD Intermediate Fixed Trunnion

- 7.00" - 8.00"

- HD Spherical Bearing

- 7.00" - 8.00"

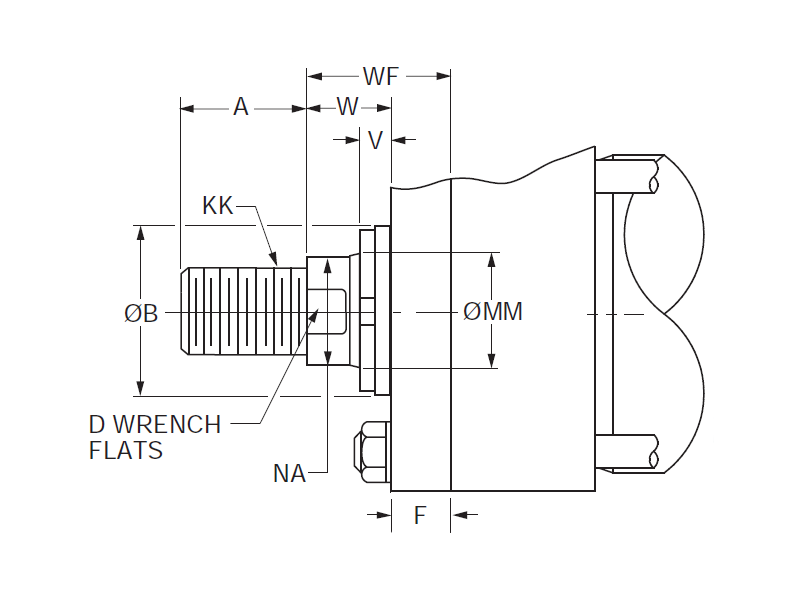

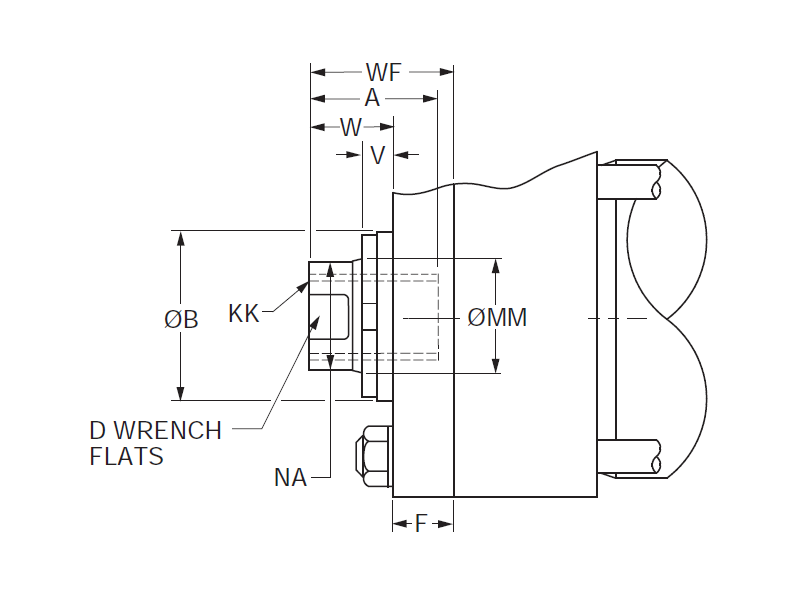

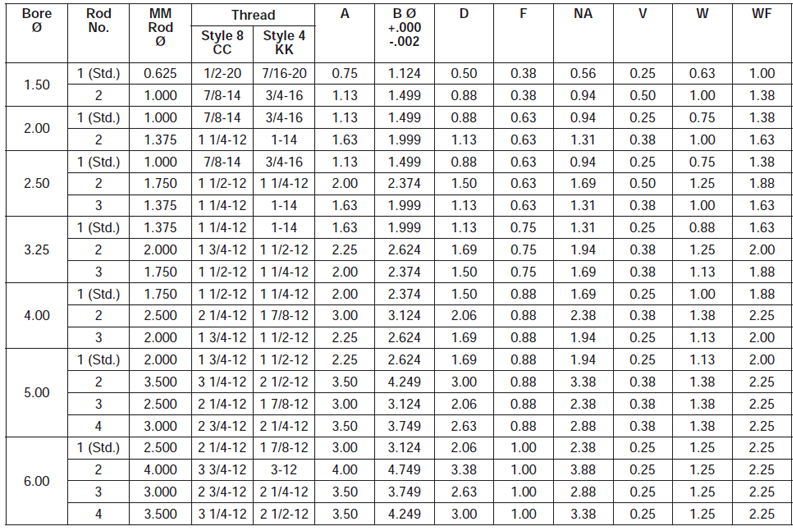

Piston Rod End Dimensions

“Special” Thread Style 3

Special thread, extension, rod eye, blank, etc., are also available.

To order, specify “Style 3” and give desired dimensions for KK, A, W or WF.

If otherwise special, furnish dimensioned sketch.

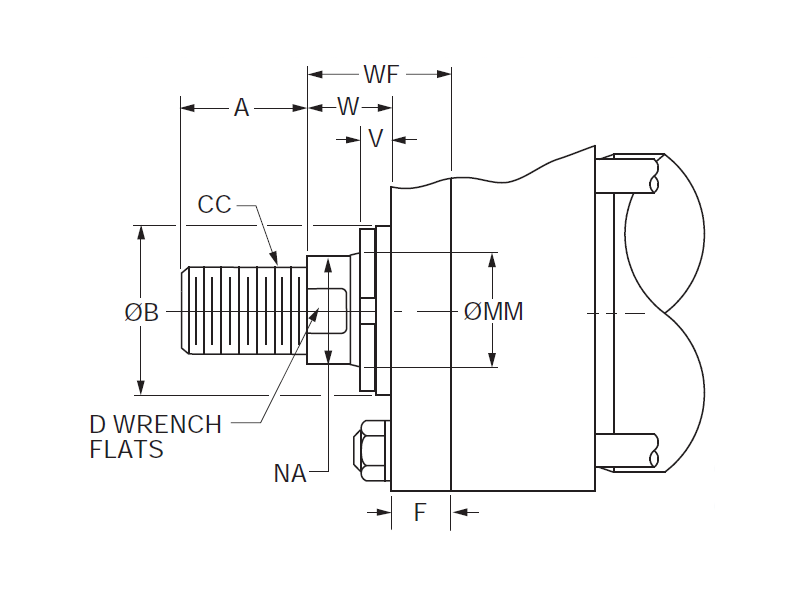

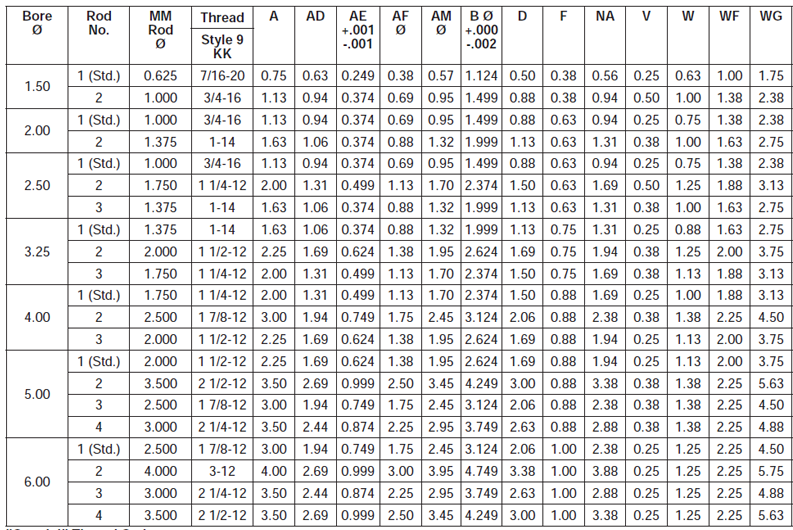

“Special” Thread Style 3

Special thread, extension, rod eye, blank, etc., are also available.

To order, specify “Style 3” and give desired dimensions for KK, A, W or WF.

If otherwise special, furnish dimensioned sketch.

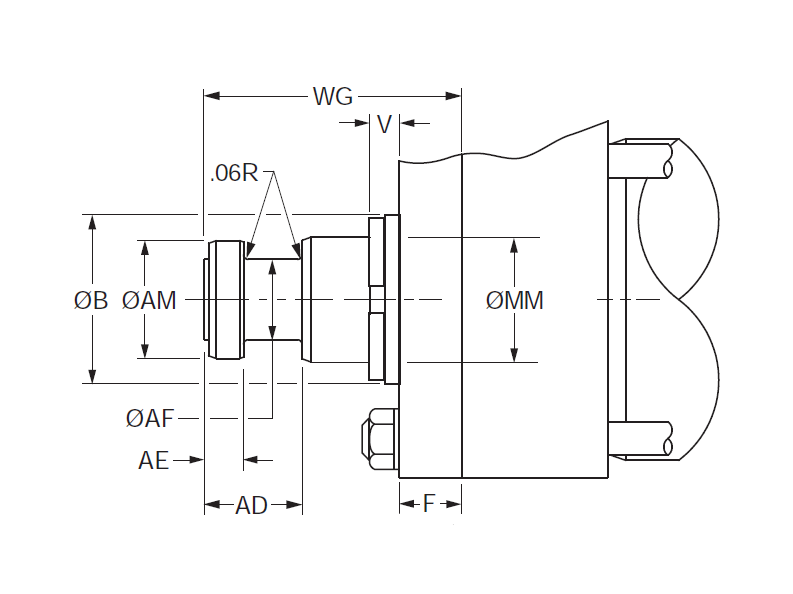

1 For special WG dimension, specify “Style 3” and give desired dimension for WG. For other changes, place “S” in the

model code, and describe rod end with dimensioned sketch.

2 Style 9 stroke restrictions may apply. See Style 9 Minimum Stroke Table on How to Order page for details.