Pneumatic Monitoring | BFM® Fitting

For Food, Chemical, Pharmaceutical & Mineral Processing Plants

Superior to traditional hose clamped canvas/cloth/rubber connectors

Superior to traditional hose clamped canvas/cloth/rubber connectors

Wherever you have a flexible connection in a live production system, if the connector is removed at any time, there is always a potential risk that hands can be placed near dangerous moving parts, such as rotary valves and rotating knives.

Now you can have added peace of mind that you can monitor when a BFM® fitting is removed in these areas with the latest innovation developed by the team at BFM®: the Pneumatic Monitoring System.

Key Features / Uses

- Designed to be a monitoring system in positions where there is a risk that hands could be placed near dangerous moving parts, such as rotary valves and rotating knives

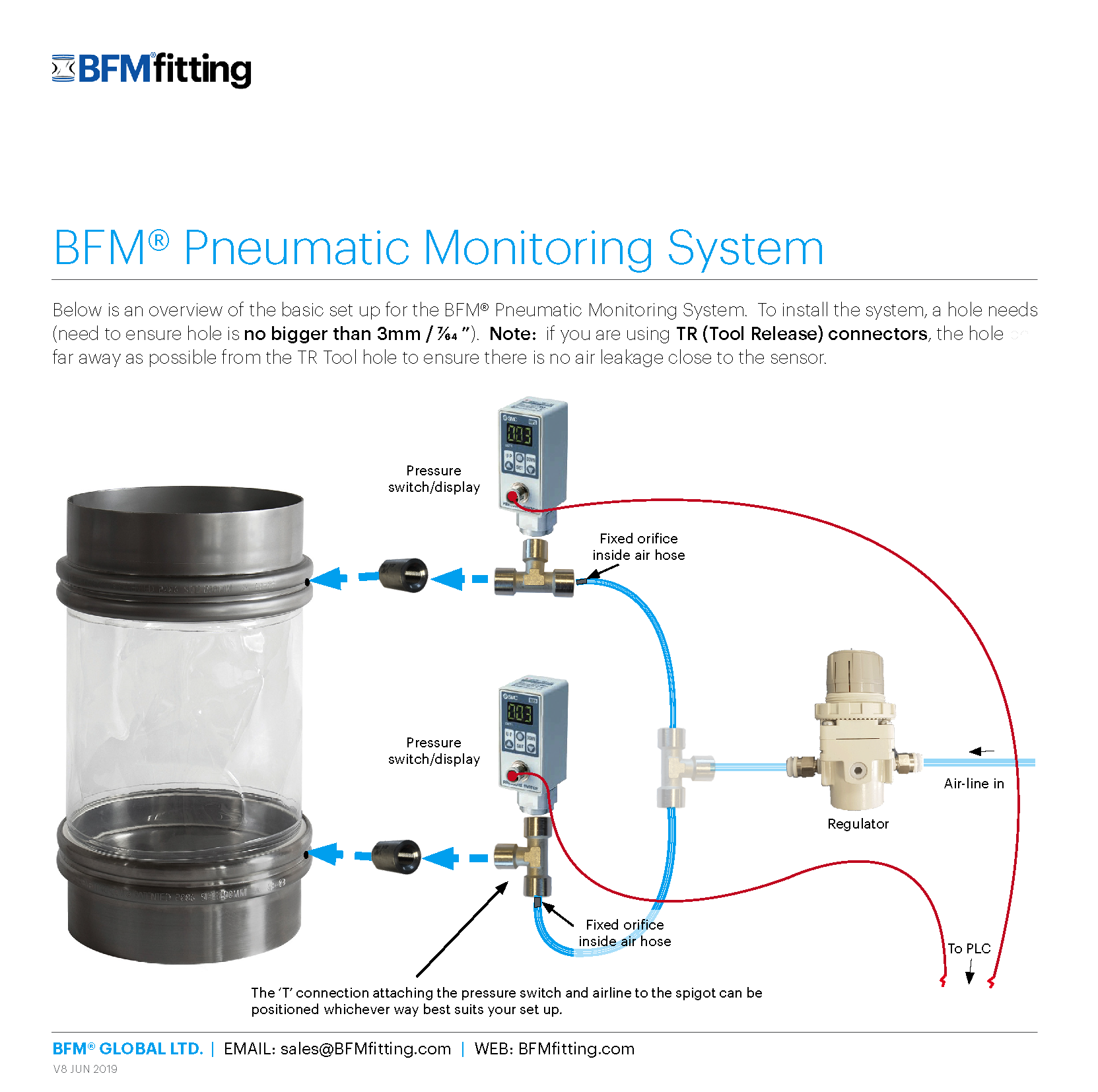

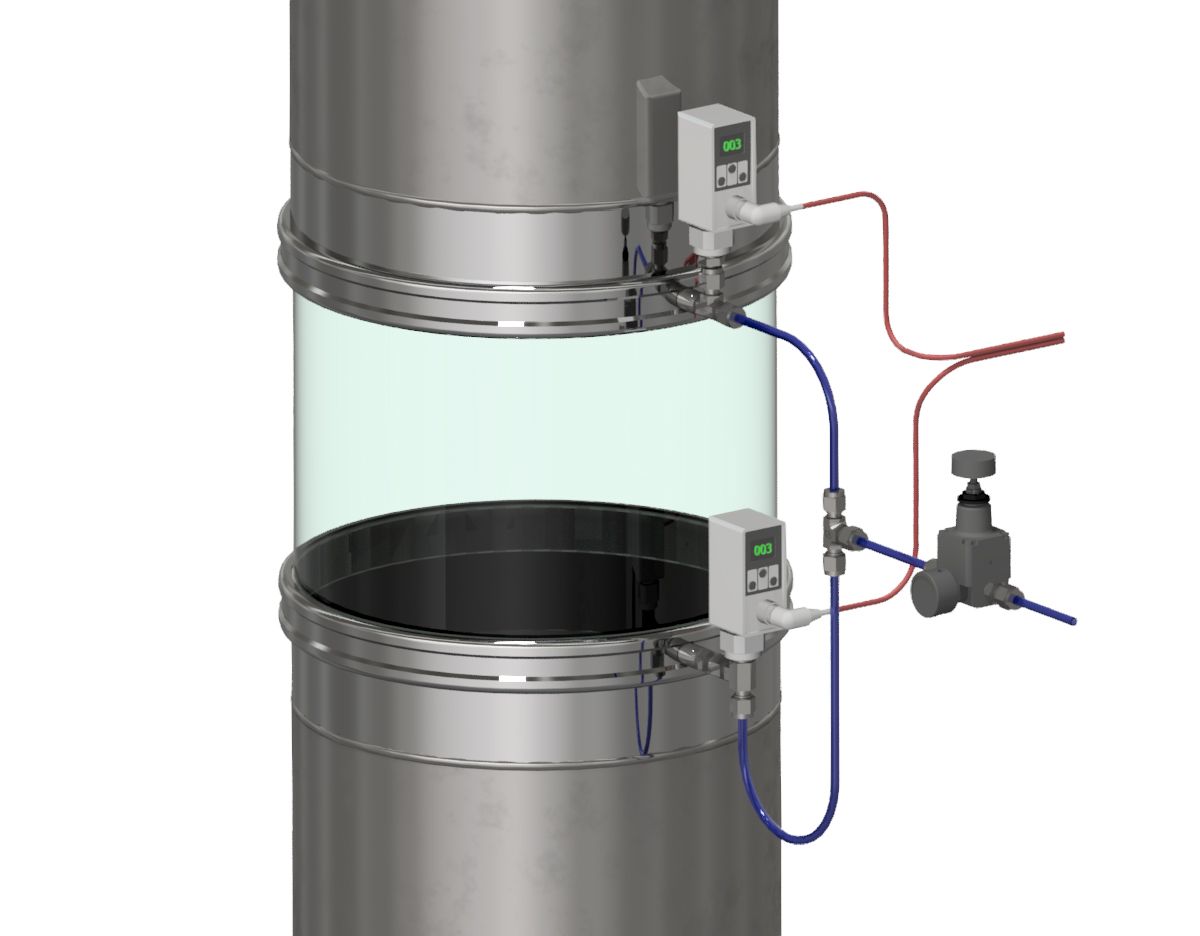

- A simple to install system that pumps pressurized air between the cuff of the BFM® connector and the spigot

- Air-line sensors immediately detect if this outward pressure is released as the connector cuff begins to pushed inwards and sets off an alarm and/or shuts off any moving parts below

- Features two pressure sensor switch/displays, and a tamper-proof gauge

- Can be used as a positional sensor to ensure all connectors in a large plant are installed correctly at all times

Two Options Available:

- IP65 Rated, Suitable for most operating environments, waterproof and dust-proof

BFM® Part No: 10400 - ATEX Category 3, II 3G Ex nA II T5 X 0°C ≤ Ta ≤ 50°C, II 3D tD A22 IP67 T53°C X

BFM® Part No: 10401