MFCP Aerospace | SEALS & GASKETS

FEATURED PRODUCTS / SPECIFICATIONS

MFCP is your reliable partner for all your Aerospace Seal and Gasket needs. Whether you need a ready-made product or a customized solution, we can deliver it to you in no time. Don’t let downtime slow you down, trust MFCP to keep you up and running.

CAPABILITIES

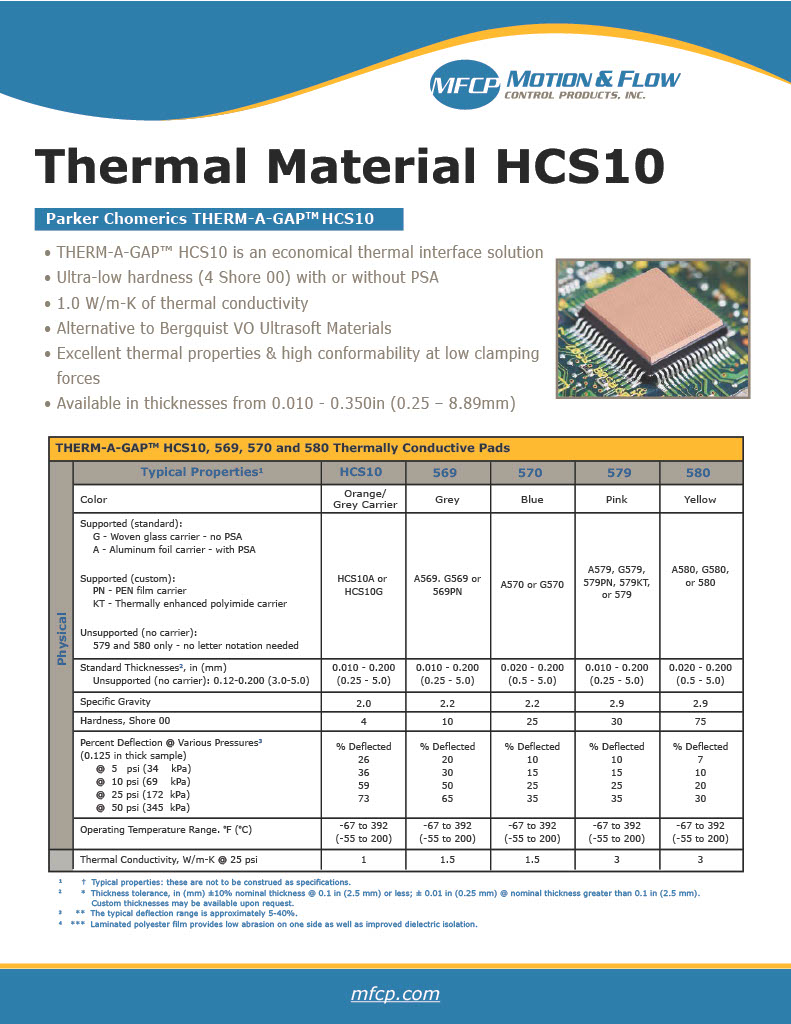

- EMI Shielding & Grounding Gaskets

- Chomerics

- SSP

- Bisco

- Formex

- Laird

- Schlegel

- Bergquist

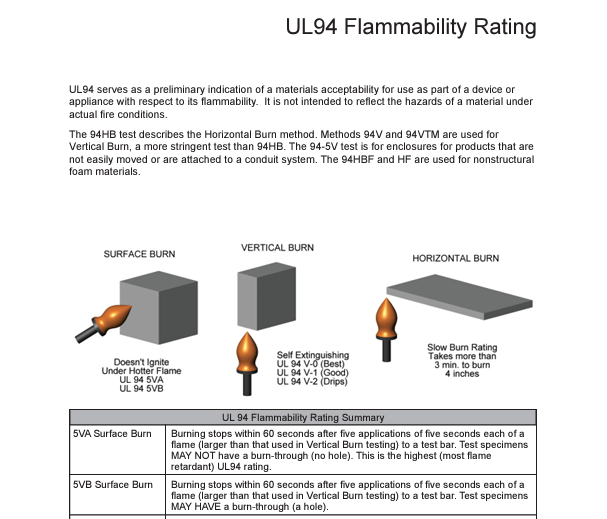

- Thermal Management Gaskets

- Electronic Closure Gaskets

- Vibration Control & Sound Dampening Gaskets

- Electrical Insulation Gaskets

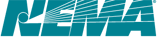

- Flame Barrier Gaskets

- Display Protection Gaskets

- Custom Conductive Gaskets

- Adhesives

- Extrusions

- Molded Rubber Parts

EMI Attenuating Ferrite Cable Chokes

EMI Shielded Air Ventilation Panels

EMI Shielding Cable Wrap

EMI Shielding Engineered Laminates

EMI Shielding Gaskets

EMI Shielding Paints

Electrically Conductive Adhesives

Ellectrically Conductive Grease

Ellectrically Conductive Heat Shrinkable Tubing

Electrically Conductive Inks

Metal Foil Tapes

Microwave Absorber Materials

Conductive Plastic Pellets and Injected Molded Plastic Solutions

Test Services for EMC Compliance and Safety

Board Level Shielding

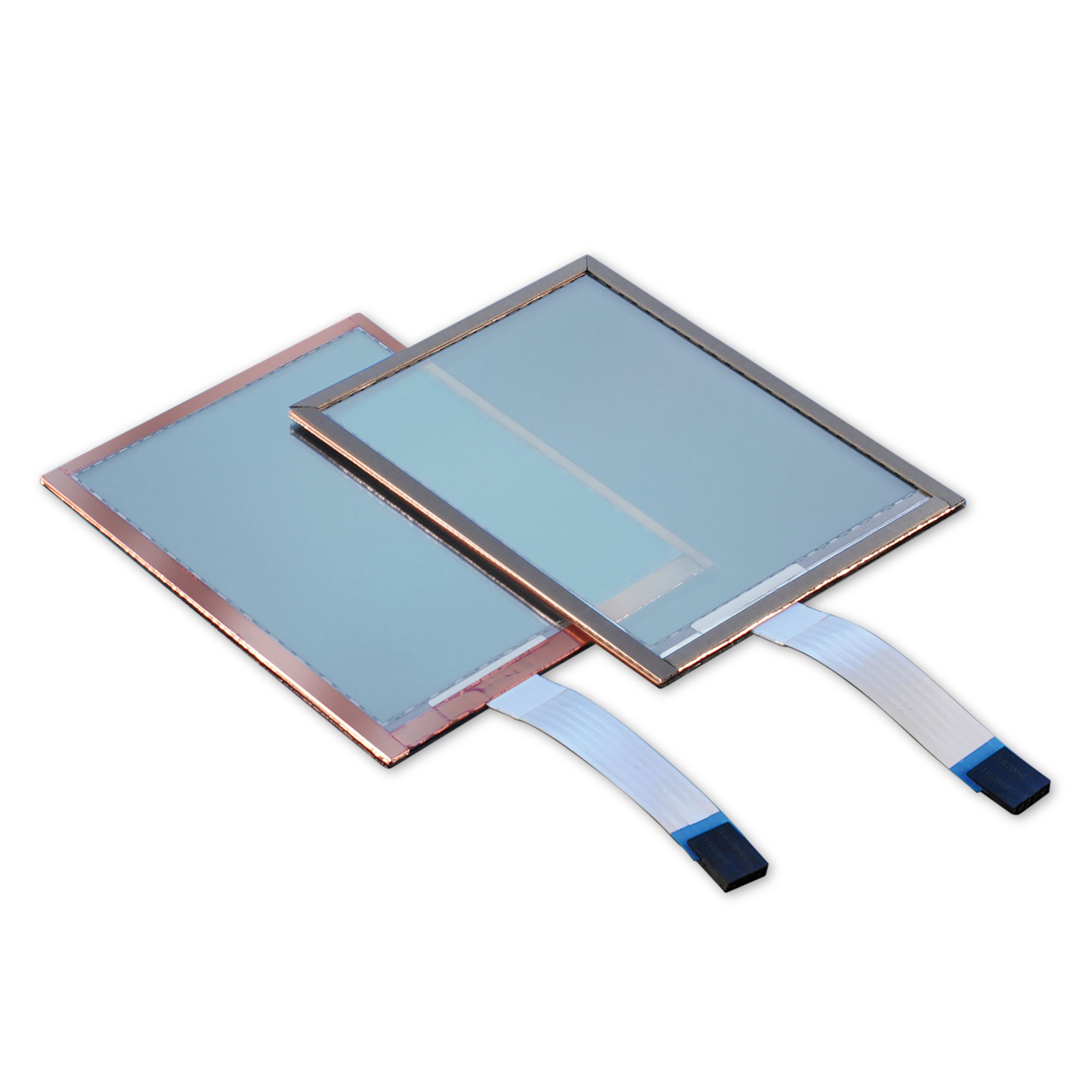

LCD Display Protection and Enhancement

HMI, Operator Panels and Touchscreens

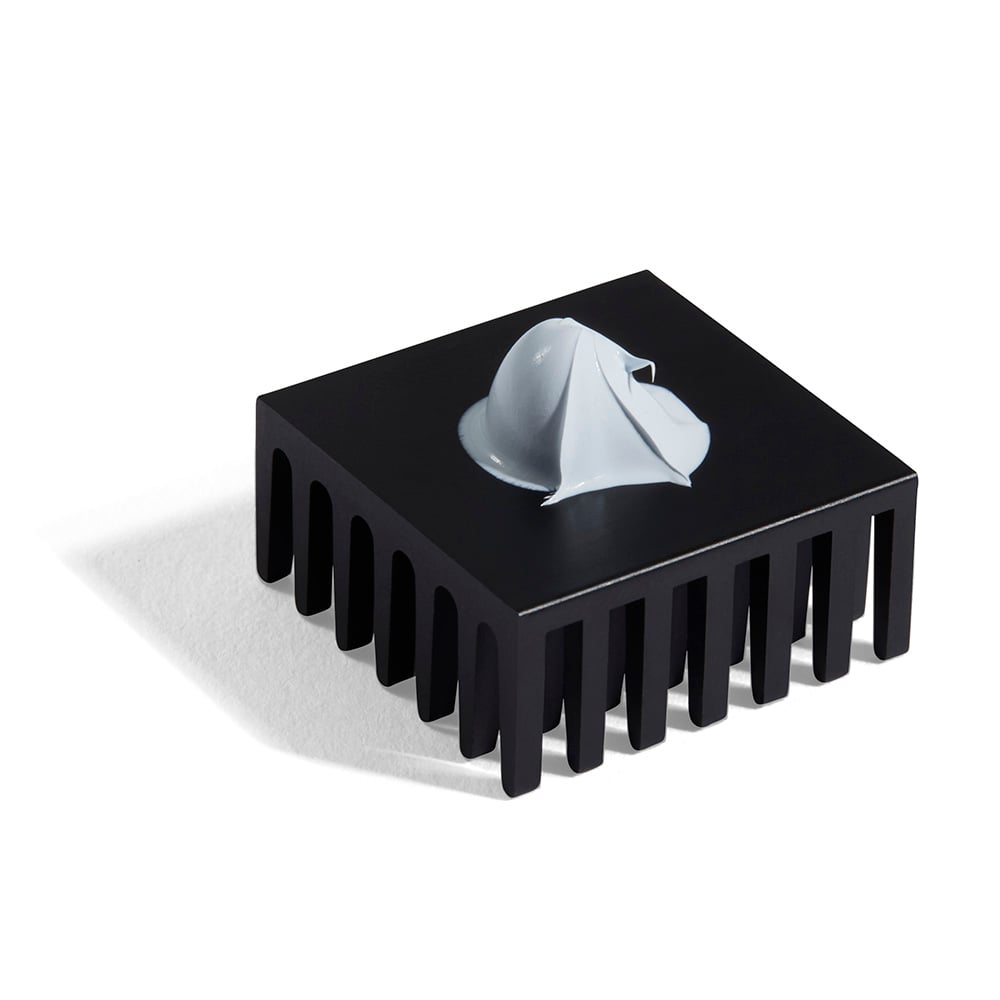

Thermal Interface Materials

METAL SEAL SPOTLIGHT

Metal seals are highly sought-after in the aerospace industry for their remarkable ability to endure extreme temperatures, pressures, and unforgiving environments. They serve as the ultimate solution for critical systems where traditional elastomeric or polymer seals fall short. Embracing the exceptional durability of metal seals, aerospace applications find their perfect match, unlocking a world of possibilities.

These are only a handful of instances in the aerospace industry where metal seals are indispensable for guaranteeing dependable performance, utmost safety, and unparalleled reliability.

Avionics and Electronics

Metal seals play a crucial role in safeguarding electronic systems and shielding them from the unforgiving aerospace environment. These robust seals are utilized in electrical connectors and cable feed-throughs, ensuring the utmost integrity and protection for your valuable equipment.

Landing Gear Seals

Metal seals are essential components in hydraulic systems of landing gear, serving the crucial purpose of preventing fluid leakage and guaranteeing seamless performance during both takeoff and landing procedures.

Cryogenic Systems

Metal seals play a vital role in cryogenic settings, particularly in the storage tanks and transfer lines for liquid oxygen and liquid hydrogen. Operating flawlessly even in the most frigid conditions, these seals offer exceptional reliability and effectively safeguard against any potential leaks.

Oxygen Systems

Metal seals play a crucial role in life support systems by effectively safeguarding against leaks and ensuring optimal pressure levels in oxygen supply lines and storage tanks.

Engine and Propulsion Systems

Metal seals play a crucial role in the intricate components of aircraft and rocket engines, including combustion chambers, fuel and oxidizer systems, and exhaust nozzles. These seals serve as guardians of system integrity, effectively thwarting leaks and guaranteeing optimal performance and safety.

Hydraulic Systems

Fuel Systems

Metal seals play a crucial role in maintaining the security and smooth flow of fuel within an aircraft or spacecraft. These robust seals are strategically employed in fuel tanks, fuel lines, and fuel control valves to guarantee safe and efficient storage and transfer of fuel.

Environmental Control Systems (ECS)

Metal seals play a crucial role in maintaining optimal temperature, pressure, and humidity levels within aircraft and spacecraft. These essential components can be found in a variety of systems including heat exchangers, pressure regulators, and air conditioning units.

CUSTOM SERVICES

At MFCP, we are fully prepared to offer our expertise in custom sealing solutions. We take great pride in our team's extensive knowledge, our efficient turnaround time, and our wide range of readily available materials.

Custom Gaskets Cut by Knife Table

Manufactures custom seals and gaskets from flexible materials and adhesives

Materials:

- EMI, ESD and Ellectrically Conductive Materials

- Thermal

- Silicone Sponges & Foam

- Flourosilicone

- Adhesives

- Closed Cell Rubber

Material Lamination

Material lamination is a process of bonding paper or other materials between layers of plastic with heat and adhesives. It is used to create custom aerospace seals that are essential for the performance, reliability, and safety of various fluid conveyance systems in aircraft, spacecraft, and satellites.

Advantages of seal lamination:

- It provides protection and durability against harsh environmental conditions, such as high temperature, high pressure, moisture, dust, and UV rays.

- It allows for different types of plastic materials and finishes to suit the specific requirements and preferences of the customers, such as polyethylene, polypropylene, polyester, vinyl, or nylon.

FEATURED SUPPLIERS

.png?width=91&height=75&name=parker-VX065-75(1).png)