Engineering Excellence: How MFCP Transformed a Customer’s Testing Capabilities

A prime example of MFCP taking on complex, high-horsepower projects is when a customer requires long-term testing on their products or systems. These fluid power systems are highly customized, challenging our sales, engineering, and production teams. Ultimately, our goal is to meet the customer's requirements and deliver the project on time.

This story begins in 2016 when Kevin Parker, then a Territory Sales Manager for our Colorado Springs location, received a call from a new customer about a busted hose on their existing test stand. Kevin's swift response and an onsite visit to measure the hose demonstrated his dedication to customer service. Over three days, he measured old hoses throughout the facility, resulting in $150,000 in hose business that year. During his inspection, Kevin also proposed discussing MFCP’s capabilities to replace the aging hydraulic power units essential for their fatigue testing.

By the end of 2016, the customer expressed interest in a Rough Order of Magnitude (ROM) to replace two power units immediately and a third in the future. Kevin collaborated with the engineering team to gather the necessary information for a quote. After another year of work on funding, Kevin received a purchase order for two power units at $205,000 each in early 2018. These units were successfully delivered on schedule in December 2018, followed by a second purchase order for the third power unit in mid-2019.

Challenges arose due to equipment and site placement, delaying the project's commissioning. Meanwhile, Kevin continued working on other projects, including a $300,000 project that shipped at the end of 2024. The customer sought to commission the power units sold five years earlier, enlisting the help of our controls engineer, Kerry Brock. Kerry made several site visits and played a crucial role in getting the units operational. Additionally, Dan Van Kempen from Aurora provided essential mechanical installation and troubleshooting support.

With a satisfied customer, MFCP is now well-positioned to replace other power units at the facility. One such unit on the docket is a 1,080 GPM, 3,000 PSI system valued at over $2 million.

The MFCP Manufacturing team is grateful for the trust Kevin Parker and others have placed in them, leading to exciting opportunities.

Unique Design

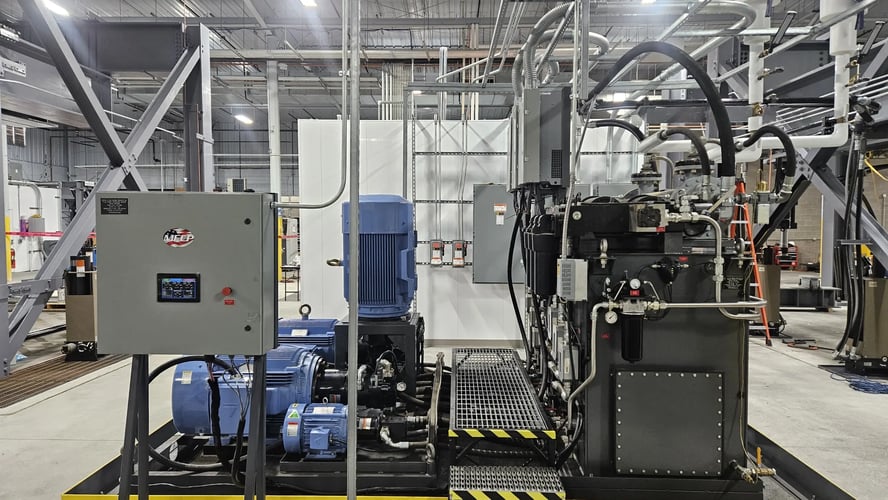

Due to space limitations and the need for operator interaction, the skid was specifically designed to fit their floor space. This layout required us to install one of the pump/motor combinations vertically. The customer was pleased with the innovative design.

Parker IQAN

Parker IQAN

Parker IQAN screens and controls are typically found on mobile hydraulic systems and in industrial applications where you would normally see a traditional PLC. Our familiarity with IQAN made it an ideal choice for this application, meeting the customer's requirements while providing the flexibility we needed to control the power unit effectively.

Employee Spotlight

This project would not have come to fruition without the creative thinking and persistent nature of Kevin Parker. He introduced this project when MFCP was not yet well-known for large system projects. Kevin's ability to think outside the box and ask probing questions has led to over $1,000,000 in business, with more million-dollar opportunities on the horizon.