Fabricating Electrically Conductive Industrial Hose Assemblies

You may recall an earlier blog about the electrical conductivity of rubber hose back in April of 2013. In this blog, we discussed that unless a hose is specifically designated as either conductive or non-conductive, you must assume that the electrical properties of the hose are not controlled during the manufacturing process, and that conductivity of the hose can change with each production run without notice. In this blog, let’s look at what can be done to make your industrial hose assembly electrically conductive for the purpose of dissipating static electricity buildup.

Before going further, here are some cautions: the movement of some particulates or liquids through a hose may cause hazardous buildup of static electricity. Uncontrolled static electricity buildup may lead to shock and/or the discharge of a spark, which could cause ignition of combustible materials that may result in property damage, injury or death. Because there are no universal electrical conductivity/resistivity standards that apply to industrial hose assemblies, applications and service, and because hose assemblies might be used in applications for which they were not fabricated, Parker suggests grounding all hose assemblies that contain grounding elements. Hose components such as helical wires and static wires may be used to safely conduct a static charge to ground. Care should be taken to properly prepare, fabricate and test industrial hose assemblies for electrical conductivity - see the guide below. Parker suggests using the following guidelines to fabricate industrial hose assemblies that facilitate dissipation of static electricity. These guidelines may be superseded by governmental, industry and/or customer requirements, regulations, specifications or standards.

Guide for Grounded Industrial Hose Assembly Fabrication

This guide is adapted from Parker Hannifin document TECH PA 2016.01.004 Industrial Hose Assembly Grounding.

Grounding is intended for static electricity dissapation purposes only - grounded hose assembly should not be substituted for an electrical conduit.

- Determine and Inspect Appropriate Hose Assembly Components

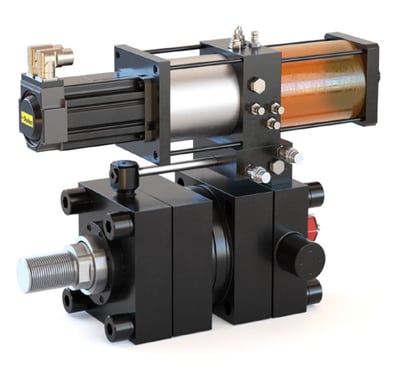

- Consult the customer/end user to obtain size, internal and ambient temperature, application description, information about media conveyed, working pressure, end configurations, delivery expectations, and all other data for the requirements of the application.

- Select the most appropriate assembly components.

- Inspect all assembly components for correct identity and size, appearance, cleanliness, quality and conformance to any required specifications.

- Determine Hose Assembly Length

- Determine the required overall length of the hose assembly for the application.

- Plan to install the hose assembly without kinking or severe bends (especially at the coupling interfaces) with enough slack to allow for contraction under pressurization and to comfortably attach the hose to connections without stretching, twisting or otherwise stressing the assembly.

- Allow for any other application-specific conditions that may apply.

- Determine Hose Cut Length

- The length of hose will be shorter than the hose assembly.

- Determine the length of hose by calculating the overall assembly length, minus the length that each coupling will be inserted into each end of hose. FORMULA: Hose Cut Length = Overall Hose Assembly Length - C1 - C2 (where C1 = Coupling length minus the insertion depth of 1st coupling, and C2 = Coupling length minus the insertion depth of 2nd coupling)

- Cut Hose

- Cut hose straight/perpendicular to its axis.

- Use a hacksaw or power-driven bladed cutting tool. CAUTION: Ends of cut wire may be sharp.

- Clean the inside diameter of the hose after cutting.

- Measure Hose Conductivity

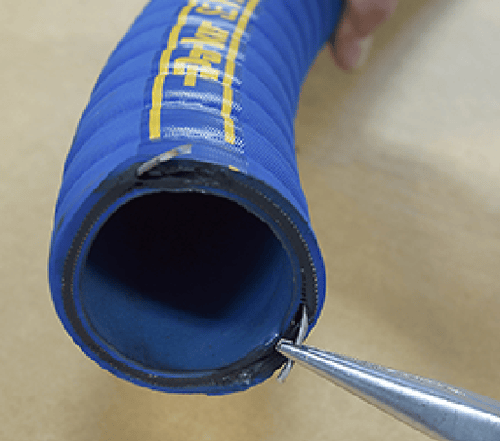

- Using pliers or other appropriate tool, manually extract all wires from the body of the hose to a length of approximately 1/2 inch.

- For thick wall hose, extracting more than 1/2 inch of wire may be required. Ensure that the length of wire does not exceed the length of the coupling shank.

- Some hoses contain more than one helical wire or more than one static wire.

- Place the hose on a clean, dry, nonconductive surface.

- Attach the metal leads of the ohmmeter at each termination of each wire.

- Apply the test voltage (9V) and measure the resistance for 5 seconds ±1 second after the voltage is applied.

- Electrical Conductivity Rating Criteria

- An application may be subject to specific conductivity requirements which take precedence: those established by federal, state or local government laws, regulations or statutes, and/or those established by industry standards organizations, and/or those established by customers/end users

- For applications not covered by the above, Parker suggests using the following measurement criteria to qualify hose assemblies: < 10 ohms resistance

- Record and safely store customer/testing data.

NOTE: The finished hose assembly also requires electrical testing.

- Fabricate Hose Assembly

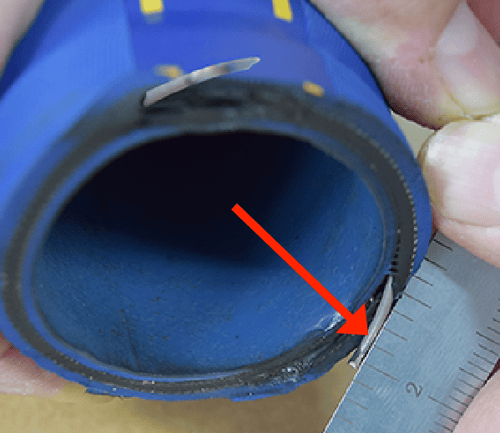

- Bend each end of wire around the wall of the hose, positioning against the inner tube of the hose. This will prepare the hose assembly for direct contact between the metal wire/metal coupling shank. For maximum contact with the inserted shank, keep the wire parallel to the axis of the hose.

CAUTION: Do not puncture the inner tube of the hose.

CAUTION: Excessive length of wire may exceed the length of the coupling shank, creating a leak path upon insertion/attachment of the shank.

- Ensure that each end of wire is securely in place and does not back out of the inside diameter of the hose before and/or during the coupling installation process.

- Apply this procedure to each end of the hose.

- Attach Couplings.

- For Parker hose, consult CrimpSource® for crimp specifications, including crimp coupling designation. Follow the CrimpSource crimp specification, and the crimp procedure shown in the Parker crimper operator’s manual.

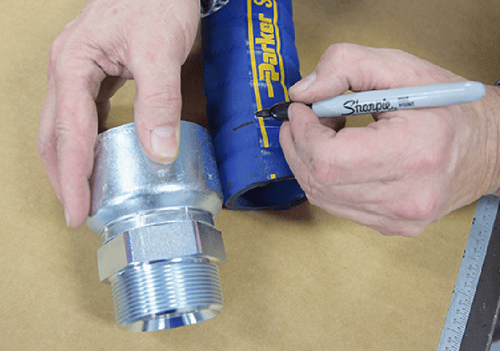

- Line up the shoulder of the ferrule at the designated position relative to the end of the hose.

- Using a grease pencil or similar marking device, mark the cover of the hose where the ferrule terminates

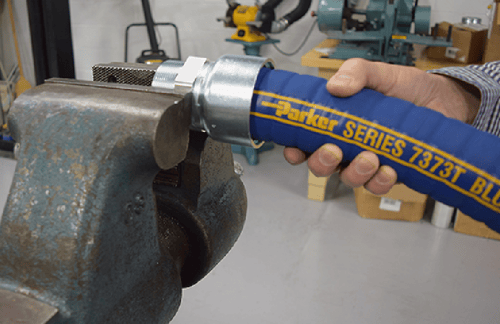

- Using a vise or similar device, secure the hose in place to prevent movement and possible damage to the inner tube of the hose during coupling insertion, and to ensure proper coupling alignment. CAUTION: Do not damage the hose in the process of securing it.

- If necessary to aid the insertion process, lubricate the inner tube of the hose and the shank of the coupling with soapy water. CAUTION: Do not cut or skive the inner tube of the hose, or file the shank of the coupling, or alter either hose assembly component in any way. Do not use other lubrication agents without first consulting the hose and coupling manufacturer. Inspect the connection to ensure there was no coupling slippage or misalignment compared to the mark on the cover of the hose.

- Apply this procedure to each end of the hose.

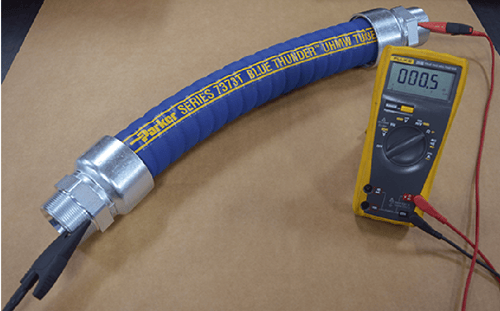

- Electrical Conductivity Measurement Procedure

- Place the hose on a clean, dry, nonconductive surface.

- It is essential that contact resistance be minimized between the end fittings and the testing instrument (ohmmeter).

- Directly attach the metal leads of the ohmmeter at each termination of each coupling.

- Apply the test voltage (9V) and measure the resistance for 5 seconds ±1 second after the voltage is applied.

- Electrical Conductivity Rating Criteria

- An application may be subject to specific conductivity requirements which take precedence: those established by federal, state or local government laws, regulations or statutes, and/or those established by industry standards organizations, and/or those established by customers/end users

- For applications not covered by the above, Parker suggests using the following measurement criteria to qualify hose assemblies: < 10 ohms resistance

- Record and safely store customer/testing data.

- Bend each end of wire around the wall of the hose, positioning against the inner tube of the hose. This will prepare the hose assembly for direct contact between the metal wire/metal coupling shank. For maximum contact with the inserted shank, keep the wire parallel to the axis of the hose.

- Install Hose Assembly in Application

- Ensure each coupling of the hose assembly maintains secure metal-to-metal contact with a grounded fixture.

User Responsibility

Due to the wide variety of operating conditions and applications for hose and fittings, Parker does not represent or guarantee that any particular hose or fitting is suitable for any specific end use system. This document does not analyze all technical parameters that must be considered in selecting components, or in fabricating and testing a hose assembly. The user, through its own analysis and testing, is solely responsible for making the final selection of products; assuring that the user’s requirements are met and that the application presents no health or safety hazards; providing all appropriate health and safety warnings on the equipment on which the products are used; and assuring compliance with all applicable government and industry standards.

More Information:

- Association of Rubber Products Manufacturers (ARPM) • Hose Handbook IP-2 arpminc.com

- International Standards Organization (ISO) • Standard 8031:2009 iso.org

- National Association of Hose and Accessories Distribution (NAHAD) nahad.org

- Parker Hannifin Corporation Industrial Hose Division • Industrial Hose Catalog 4800 • Parker Safety Guide 4400-B.1 safehose.com