Inventory Reduction of Bulk Hydraulic Hose with Parker GlobalCore

Most maintenance managers and other professionals responsible for keeping machinery running are not likely to agree with accountants on the quantity of spare parts needed in stock. Accountants try to limit inventory of parts on hand, which in some cases sit around for months before being used. The accountants recognize that stocking large quantities of spare parts ties up company’s money in inventory and decreases the company’s profitability.

On the other hand, maintenance professionals often need to have a large quantity of parts on hand in order to keep the machinery running and down-time to a minimum. Since they have no way of knowing which machine will break down next, and which parts will be needed to fix it, inventory reduction is not high on their list of improvements. Machinery sitting idle while waiting for a replacement part can also kill profits in a hurry.

Both the accountants and the maintenance staff have a point. The challenge for MRO organizations is finding the right balance of stocking enough parts to not run out without tying up too much cash in the inventory.

When considering the stock of hydraulic hose in bulk, maintenance managers need to consider not only different hose styles and sizes that will do the job, but also hose fitting sizes and configurations needed to fabricate replacement hose assemblies. The problem for the inventory situation is that different hoses are typically engineered to work only with specific hose fittings. True, you should never attempt to use incompatible hose and fittings together, as this can lead to potentially dangerous and expensive hose assembly failures, but the fact remains that it takes a lots of different hoses and fittings to be prepared for unexpected breakdowns.

Fortunately, there is a relief in sight, at least for the stock of hydraulic hose fittings. The solution comes in form of Parker GlobalCore family of hoses with 43 series and 77 series fittings, both engineered to work with multiple styles of hoses. Consider the following example:

You need to be able to fabricate hose assemblies in 1-1/4”, 1-1/2”, and 2” diameter, with either straight, 45˚ elbow or 90˚ elbow fittings, and with working pressure rating of 4,000 PSI, 5,000 PSI or 6,000 PSI.

Scenario 1 – Business as usual:

You will need to stock three styles of hoses in three sizes (9 inventory items). You will also need to store three configurations of fittings for each of the nine hoses (27 inventory items).

Scenario 2 – Using a fitting, which can be crimped on any of the three styles of hoses:

You will still need to stock the three styles of hoses in all three sizes, which is still nine line items on your inventory list. However, you will only need nine style/size combinations of fittings (9 inventory items compared to 27 in the first scenario). All you will need now are three sizes of straight fittings, three sizes of 45˚ elbows, and three sizes 90˚ elbows, because the same fitting can be used for any of the three style hoses of matching size.

In the second scenario, the number of fitting inventory line items was reduced from 27 to 9. For most shops, this does not translate to 66% less inventory - but for some, it could. Most shops will need to increase the number of fittings stocked for each of the nine inventory items. How much will depend on how often a hose assembly needs to be replaced and how quickly can inventory be replenished. Busy shops will need to increase inventory more than shops fabricating one or two hose assemblies per week. Also, the longer the lead time for replenishing your inventory, the more parts you need to keep on hand in order not to run out. Typically, the overall cost of inventory will decrease significantly under the second scenario, because the total number of fittings needed in stock decreases with the number of stocked fitting line items.

Parker GlobalCore Hoses

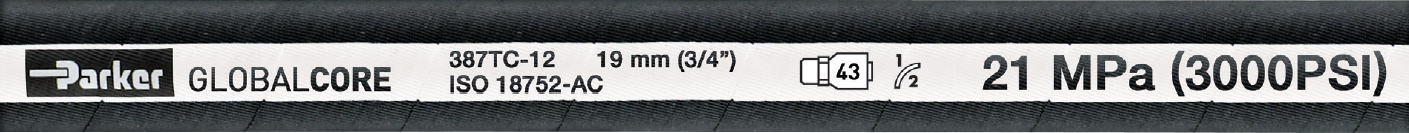

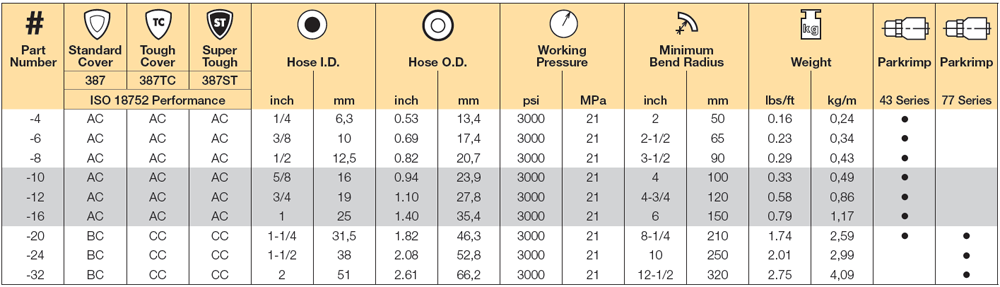

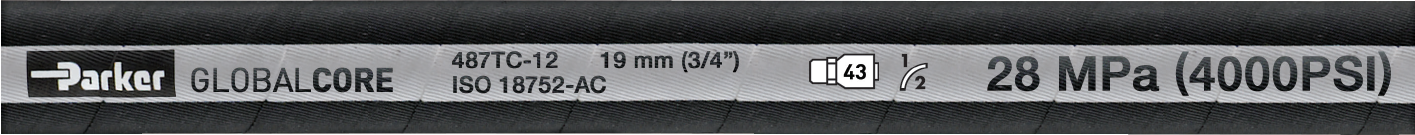

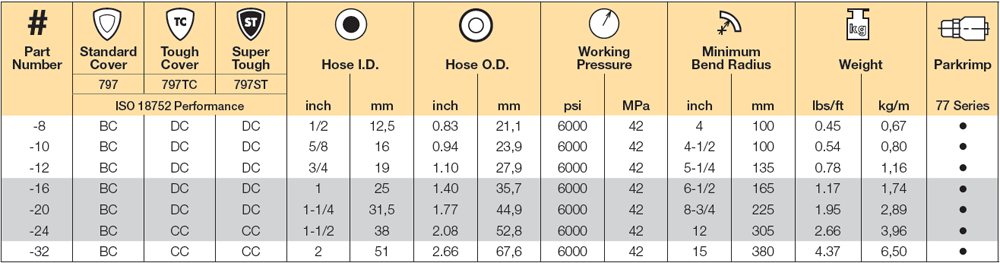

Parker Global Core is a family of six hydraulic hoses (187 Series - 1,000 PSI, 387 Series – 3,000 PSI, 487 Series – 4,000 PSI, 722 Series – 4,000 PSI, 787 Series – 5,000 PSI, and 797 Series – 6,000 PSI) which are engineered to work with just two different hose fitting styles (43 Series and 77 Series). The Global core hoses cover the most common pressure ranges required by today’s machinery in sizes from ¼” to 2”. All hoses are a no-skive design.

387 Hose - ISO 18752 - AC/BC/CC

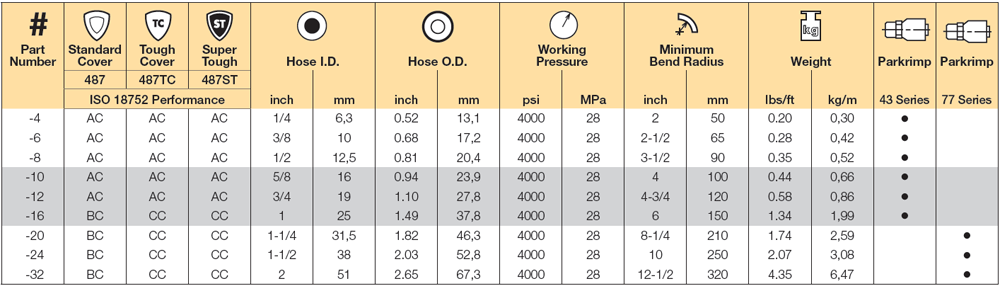

487 Hose - ISO 18752 - AC/BC/CC

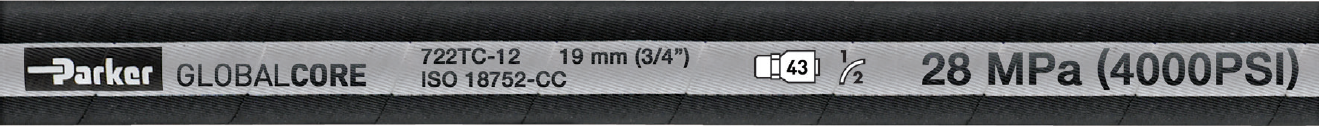

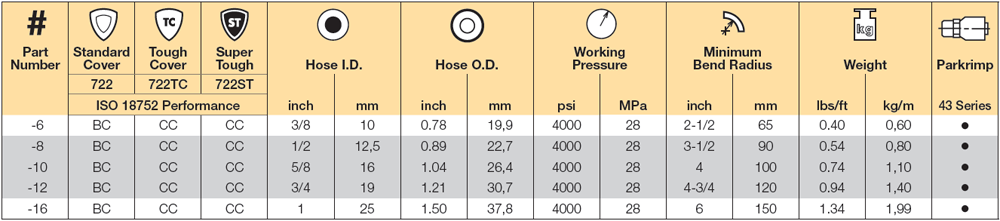

722 Hose - ISO 18752 - BC/CC

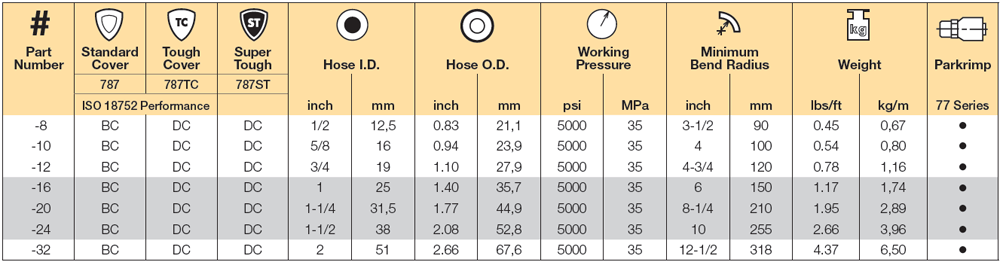

787 Hose - ISO 18752 - BC/DC

797 Hose - ISO 18752 - BC/CC/DC

An added benefit of Parker Global Core hoses is their compact spiral design, featuring smaller outside diameter and half the minimum bend radius prescribed by the industry specs.

To see if your organization can benefit from converting to the Parker Global Core family of hoses, schedule an evaluation of your inventory and your hose assembly needs by emailing hfe@hfeweb.com or click below to start the process online.

Posted by Marek Bobik