Hammer Union Hose Connections for the Oil, Gas and Cement Industry

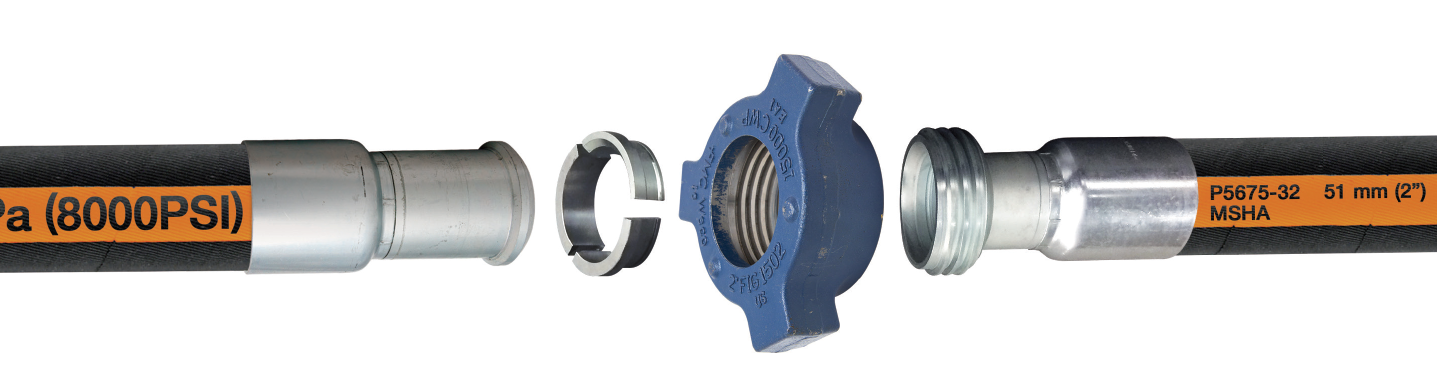

Hammer Union Connections

- Ideal for the oil and gas industry

- One piece, segmented design

- Strong industrial grade steel

- Durable and resistant to hammer connection

- 90° hammer union connection “HB”

- 45° fatigue resistant hammer union connection “HE”

- Wingnut is not captive on hose assembly

- Easy removal of wingnut for replacement or rework

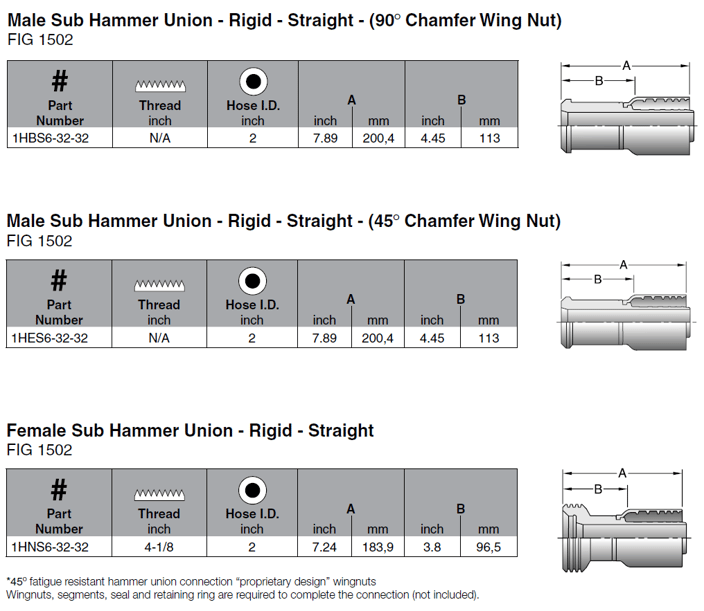

Hammer union connections require strong components to withstand the pounding required to make the connection. Parker uses 4340 industrial grade steel to give the fitting extra strength. This material has been field tested and specified by the leaders in the Cementing sector.

S6 series hammer union fittings specifically incorporate a segmented design to make installation and repairs simple. Removal of the segments allows the wing nut adapter to be disassembled from the hose, allowing easy replacement or rework of the wing nut without having to modify the hose assembly.

Two styles of male sub hammer union fittings are provided for either 90˚ chamfer wing nut, or 45˚ chamfer wing nut.

Parker S6 series connections are engineered to work with the following hoses:

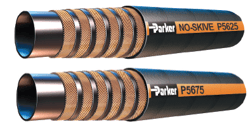

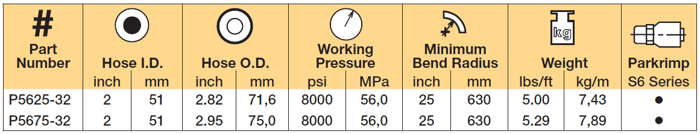

P5625/P5675 Hose - 8,000 PSI

Designed for high pressure pumping applications up to 8000 PSI

P5625 has a super tough cover for long lasting abrasion resistance.

P5625 No-Skive design eliminates the need to remove the hose cover before crimping.

P5675 has an extremely thick super tough cover designed for ultra-abrasion resistance.

P5675 requires skiving of the external cover before crimping.

- Application: Cement slurry, mud service

- Inner Tube: Synthetic rubber

- Reinforcement: Four or six spiral steel wire

- Cover: Synthetic abrasion resistant rubber

- Temperature Range: -4°F to +158°F (-20°C to +70°C)

- Safety Factor: 2.5:1

- Fittings: S6 Series

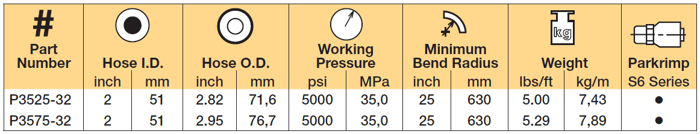

P3525/P3575 Hose - 5,000 PSI

Designed for high pressure pumping applications up to 5000 PSI

P3525 has a super tough cover for long lasting abrasion resistance.

P3525 No-Skive design eliminates the need to remove the hose cover before crimping.

P3575 has an extremely thick super tough cover designed for ultra-abrasion resistance.

P3575 requires skiving of the external cover before crimping.

- Application: Cement slurry, mud service, water, petroleum based hydraulic fluids and lubricating oils

- Inner Tube: Synthetic rubber

- Reinforcement: Four or six spiral steel wire

- Cover: Synthetic abrasion resistant rubber

- Temperature Range:

- Cement delivery -4°F to +158°F (-20°C to +70°C)

- Petroleum based hydraulic fluids -40°F to +257°F (-40°C to +125°C)

- Water, water/oil emulsion and water/glycol hydraulic fluids

-40°F to +158°F (-40°C to +70°C)

- Safety Factor: 4:1

- Fittings: S6 Series