Aerospace Thread-Lok Quick-Disconnect Couplings | Parker Stratoflex

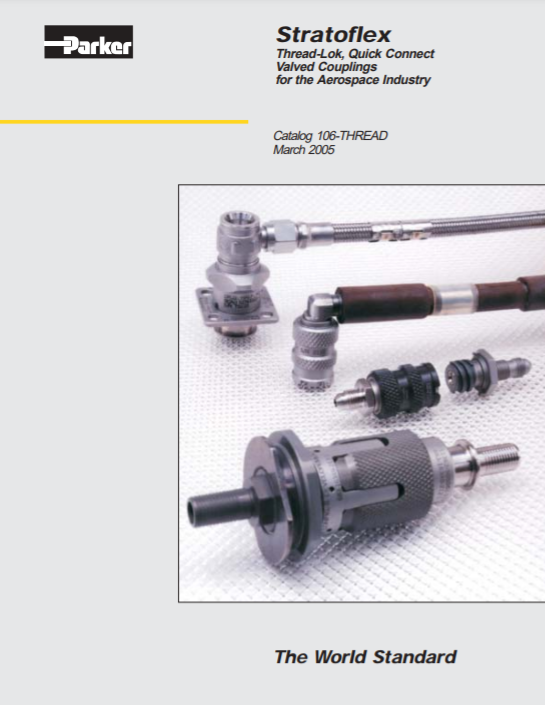

Parker Stratoflex’s Thread-Lok quick disconnect (QD) couplings provide a proven solution for fluid conveyance systems when envelope and weight are important and robust performance is critical. Thread-Lok uses the same high performance internal valve design from the IndiLok and SlideLok QDs, and provides a highly reliable and robust positive locking mechanism to ensure the performance needed in difficult aircraft system environments. These challenging environments include the engine nacelle, landing gear and brake systems, and other installations where demands on the QD are high. The Thread-Lok QD is used in a wide range of pressure and temperature applications.

Parker Stratoflex Thread-Lok QDs use proven engineering and design experience to provide a simple one-hand operation to thread the QD halves together with a visual confirmation of proper and full coupling to improve both time and safety. The Thread-Lok design incorporates tang and slot design, which engage when the coupling halves are threaded together and fully connected. When the QD halves are fully connected, the slot (coupler-hose half) is engaged with the tang (nipple-bulkhead or manifold half) to provide both visual and touch indication of the fully connected position.

The QD can only engage and lock in one position with the tang and slot, to confirm full connection and full internal valve open flow position. The engaged slot and tang also provide a secondary locking in the connected position, preventing the coupling halves from unintentional uncoupling due to vibration in service.

Thread-Lok couplings use Parker’s efficient, self-sealing valve design that permits fluid flow with minimum pressure loss and turbulence. Flush-faced valve design also minimizes air inclusion or spillage during coupling or uncoupling. The design allows for simple, one-handed operation to connect (thread clockwise) or disconnect (pull back on the outer actuating sleeve and thread counter clockwise) the coupling halves during installation or maintenance on the fluid system.

As the coupling halves are threaded together, the internal fluid flow path opens; when in the fully open position, the coupling halves are locked together using Parker Aerospace’s reliable and high-strength acme threads. The acme threads provide robust performance in harsh environments, along with making it impossible to cross thread during connection, as can be the case with finer thread products. Typical installations use the coupler half with latching mechanism on the hose or tube side, and the nipple half installed on a panel or in a manifold.

The Thread-Lok quick disconnect requires linear movement to connect and disconnect along with room to access the outer, or actuating sleeve, by hand in order to pull back the sleeve and rotate to disconnect the two halves.

Tech Specifications:

MATERIALS OF CONSTRUCTION: Stainless steel or other materials specified

FOR FLUID TYPE: Hydraulic, fuel, and cooling system applications

Features & Attributes

- Provides ease of maintenance in fluid systems allowing modular replacement of key equipment why sealing fluid in the disconnected position. Prevents fluid loss and need to bleed system when reconnected.

- Designed to protect system integrity without restricting fluid flow rate or operation

- Engineered, tested, and constructed to provide long-term, reliable service for both high-rate cycling systems and continuous-flow systems.

- Protects key components and subsystems within fluid conveyance systems

- Thread to connect with positive visual and touch indication of fully connected and latched position

- Meets performance requirements of SAE specification AS1709

- Small and very efficient size and flow-rate combination, ideal for hydraulic, fuel and cooling system applications

- Low pressure drop based on streamline valve design

- Simple, one-hand connect and disconnect operation for ease of use

- Range of end-fitting styles and fluid-compatibility options available

- Stainless steel construction meets typical electrical bonding requirements

Applications

The Parker Aerospace Thread-Lok QDs are used on a variety of aerospace and related applications where positive indication of latching is important. Along with robust performance in harsh environments, their small size, light weight, and high reliability are important for systems in service today. Programs include Boeing 737NG, 777, 747-400, 787, Airbus A380, A350, Embraer 175/190, commercial jet brake systems and a wide range of cooling system fluids (PAO, EGW, PGW) and military applications including P-8A, F-22, F-35, B-1B, C-130, C-5RERP, H-92 and others.

Optional Features

Standard configuration is available in stainless steel body construction. Component materials include stainless steel and other materials compatible with specific fluid applications. Contact Stratoflex Products Division for any other specific material information.

The Thread-Lok QD series has been proven over years of service, with a history of reliability both in the air on the ground. The baseline qualification for this product is based on the applicable requirements of industry standard SAE AS1709 specification. In some cases, qualification is based on or may be required for specific platform installation and performance requirements. Contact Stratoflex Products Division with interface and performance requirements to determine if this product is the best choice for your installation and application.

The best choice where high vibration, shock, and impulse load environments exist, Parker Aerospace recommends the Thread-Lok quick disconnect coupling series. The mechanical advantage of connecting the coupling halves with a thread-together design, often provide the most robust performance in systems including engines, landing gear and brake systems.