Hydraulic & Pneumatic Systems Diagnostic Tools

Diagnosing a problem before the system failure occurs should be the primary objective of anyone charged with equipment or machinery maintenance. Up-time is what makes money, down-time is what kills productivity.Parker Senso Control Meters

|

SensoControl Owner's Manuals |

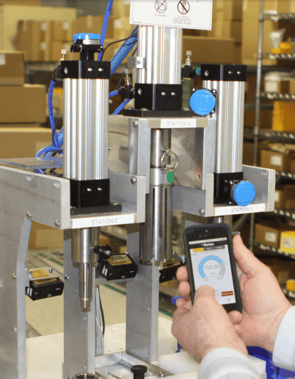

Parker's Senso Control family of diagnostic meters and kits is geared toward helping you find problems in hydraulic and pneumatic systems before they cause work stoppage. Our experts can help you select the right diagnostic tools for your system, and even train your mechanics after the purchase.

Parker Senso Control diagnostic meters provide fast and accurate measurements of pressure, flow, temperature, and rotational speed (RPM).

For more information, follow the links in the right margin, call 888-715-4673, or Email Our Senso Control Expert.

Wireles Sensors for Gas & Liquid Systems | Parker SensoNode

For more information, follow the links in the right margin, call 888.715.4673, or Email Our Senso Control Expert.

Compressed Air System Remote Monitoring | Transair SCOUT

For more information, follow the links in the right margin, call 888.715.4673, or Email Our Senso Control Expert.