Parker 30 Series Pneumatic Couplings | General Purpose - Push-to-Connect

|

Parker 30 Series couplers are designed for rigid mounting that allows a simple push-to-connect operation.

30 Series QC Dimensions & Specifications:

Choose another GP - Push-To-Connect QC Choose another Pneumatic QC Go back to Product Overview |

Parker 30 Series has a locking mechanism that consists of pawls (or pins) which act directly on the sleeve, thereby causing the sleeve to automatically retract when the mating nipple is inserted.

30 Series couplings are push type Single Shut-Off couplings and mate with industrial interchange design nipples. .

Common applications: compressed air, water, grease, paint, limited vacuum and limited gases.

Parker 30 Series Couplings Specifications & Performance

| Body Size (in.) 1/4 | 1/4 | 3/8 | 1/2 | 3/4 |

| Rated Pressure (PSI) | 300 | 300 | 300 | 300 |

| Temperature Range (Std. seals)* | -40° to +250° F. | |||

| Locking Device | 3 pawls | 4 pawls | 5 pawls | 6 pawls |

| Vacuum Data (inches Hg) Disconnected (coupler only) Connected | Not recommended |

|||

| 27.4 | 27.4 | 27.4 | 27.4 | |

Parker General Purpose Pneumatic Coupling Repair Kits

The repair kits below are for Parker 10, 20, 30, 50, 70, & TL Series Pneumatic Couplings.

| Body Size |

Seal Material |

Part No. |

| 1/4 | Nitrile | 21K |

| 1/4 | Ethylene Propylene | 21KW |

| 1/4 | Fluorocarbon | 21KY |

| 3/8 | Nitrile | 14K |

| 3/8 | Ethylene Propylene | 14KW |

| 3/8 | Fluorocarbon | 14KY |

| 1/2 | Nitrile | 16K |

| 1/2 | Ethylene Propylene | 16KW |

| 1/2 | Fluorocarbon | 16KY |

| 3/4 | Nitrile | 38K |

| 3/4 | Ethylene Propylene | 38KW |

| 3/4 | Fluorocarbon | 38KY |

30 Series Couplings Options

Add the suffix “N” as well as the “B” prefix to order an all brass coupler with stainless steel locking balls and springs, Example: B33N.

All-brass 30 Series Couplings should be used to avoid corrosion from moisture. Contact us for specific recommendations.

SLEEVE-LOK

All sizes of 10, 20, 30, 50, and 70 Series couplers can be furnished with Locking Sleeves, as illustrated.

Place suffix letters -“SL” (Sleeve-Lok) after regular catalog number. Example: B33-SL.

Orders & Quotes

|

|

|

When ordering quick couplers, consider the following:

- Functional requirements of the coupling

- Maximum working pressure of the application

- Coupler seal & body material compatibility with the system’s fluid

- Is the application static or dynamic?

- Size of coupler & hose

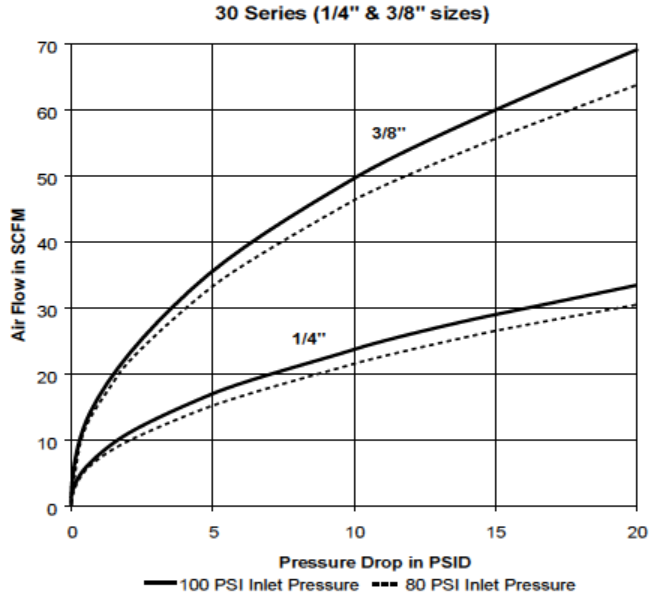

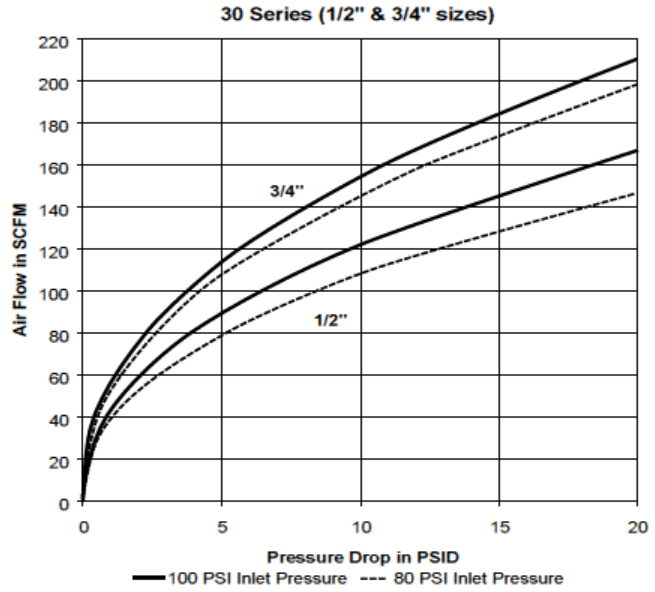

- Maximum allowable pressure drop

- Requirement to connect & disconnect under pressure

- Media temperature

- Ambient temperature

- End configuration requirements

- Need for industrial interchange QC

- Effects of air inclusion & fluid loss