Parker Twist-Lock Series Pneumatic Couplings | General Purpose - Push-to-Connect

|

Parker Twist-Lock Series Push-to-Connect design is meant for easy, one handed operation.

Twist-Lock Series QC Dimensions & Specifications:Choose another GP - Push-To-Connect QC Choose another Pneumatic QC Go back to Product Overview |

Parker Twist-Lock series has a variety of port configurations that are available to meet specific needs.

Twist-Lock series has zinc bodies with Chromium-6 Free plated steel sleeves and nipples. It is designed to protect against accidental uncoupling.

Common applications: compressed air, water, grease, paint, limited vacuum and limited gases.

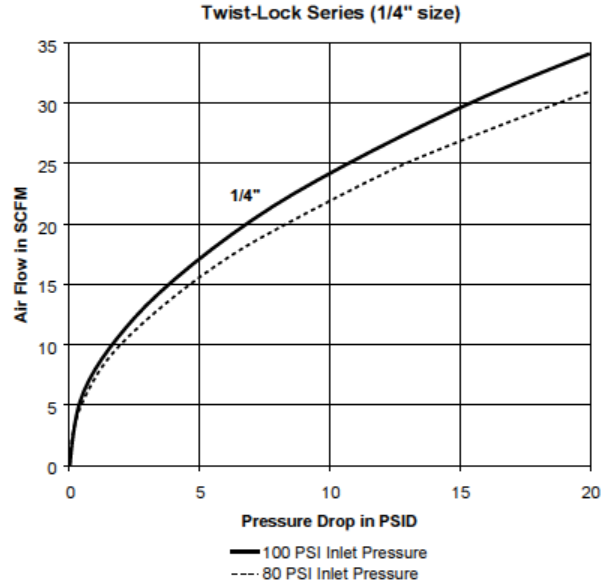

Parker Twist-Lock Series Couplings Specifications & Performance

| Body Size (in.) | 1/4 | 1/2 |

| Rated Pressure (PSI) | 300 | 300 |

| Temperature Range (Nitrile seal) | -40° F to +250° F. | |

| Locking Device | CAM | |

| Vacuum Service | Not Recommended | |

Parker General Purpose Pneumatic Coupling Repair Kits

The repair kits below are for Parker 10, 20, 30, 50, 70, & TL Series Pneumatic Couplings.

| Body Size |

Seal Material |

Part No. |

| 1/4 | Nitrile | 21K |

| 1/4 | Ethylene Propylene | 21KW |

| 1/4 | Fluorocarbon | 21KY |

| 3/8 | Nitrile | 14K |

| 3/8 | Ethylene Propylene | 14KW |

| 3/8 | Fluorocarbon | 14KY |

| 1/2 | Nitrile | 16K |

| 1/2 | Ethylene Propylene | 16KW |

| 1/2 | Fluorocarbon | 16KY |

| 3/4 | Nitrile | 38K |

| 3/4 | Ethylene Propylene | 38KW |

| 3/4 | Fluorocarbon | 38KY |

Orders & Quotes

|

|

|

When ordering quick couplers, consider the following:

- Functional requirements of the coupling

- Maximum working pressure of the application

- Coupler seal & body material compatibility with the system’s fluid

- Is the application static or dynamic?

- Size of coupler & hose

- Maximum allowable pressure drop

- Requirement to connect & disconnect under pressure

- Media temperature

- Ambient temperature

- End configuration requirements

- Need for industrial interchange QC

- Effects of air inclusion & fluid loss