Parker VDHA | 24° Flareless High Pressure Valves for Metric Tubing | Parker EO-2

|

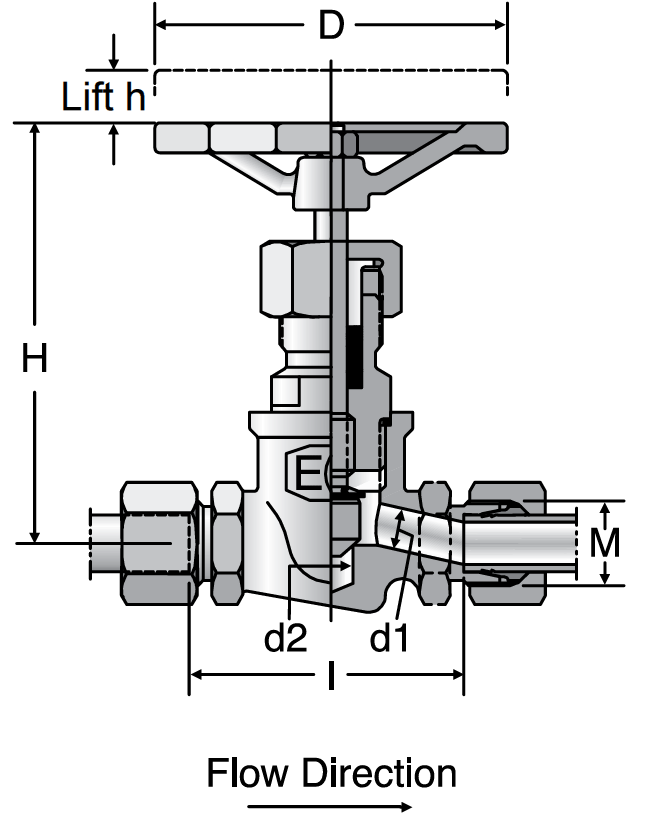

Bite-Type High Pressure Valves Part #: VDHA

24° Flareless / 24° Flareless |

|

TUBE |

END |

DN |

d1 |

d2 |

D |

h |

H |

I |

Pressure |

|

|

EO |

EO-2 |

|||||||||

|

CF |

CF |

|||||||||

|

VDHA06ZS |

6 |

3 |

4 |

9.5 |

100 |

6 |

120 |

66 |

630 |

630 |

|

VDHA08ZS |

8 |

4 |

5 |

9.5 |

100 |

6 |

120 |

66 |

630 |

630 |

|

VDHA10ZS |

10 |

6 |

7 |

9.5 |

100 |

6 |

120 |

65 |

630 |

630 |

|

VDHA12ZS |

12 |

8 |

8 |

9.5 |

100 |

6 |

120 |

65 |

630 |

630 |

|

VDHA14ZS |

14 |

10 |

10 |

9.5 |

100 |

6 |

120 |

84 |

630 |

630 |

|

VDHA16ZS |

16 |

12 |

11 |

9.5 |

100 |

6 |

120 |

83 |

400 |

400 |

|

VDHA20ZS |

20 |

16 |

13 |

11.0 |

100 |

6 |

120 |

79 |

400 |

400 |

|

VDHA25ZS |

25 |

20 |

17 |

12.0 |

125 |

9 |

143 |

106 |

400 |

400 |

|

VDHA30ZS |

30 |

25 |

19 |

22.5 |

125 |

12 |

164 |

103 |

250 |

250 |

|

VDHA38ZS |

38 |

32 |

25 |

26.5 |

180 |

12 |

198 |

118 |

250 |

250 |

Tube Fittings

- Select another EO-2 Fitting

- Select EO Fitting (Bite type fitting for metric tubing - NO elastomeric seal)

- Select Ferulok Fitting (Bite type for inch tubing)

- Select Intru-Lok Fitting (Bite type fitting for brass, copper, aluminum and plastic inch tubing)

- Select Another Tube Fitting Type

- Go To Product Selection Page

24° Flareless | Parker EO-2

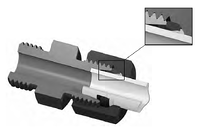

The EO-2 series are high-pressure metric tube fittings combining bite type technology with elastomeric seal on all joints.

The EO-2 fittings are true metric design, conforming to 24° bite-type standards such as ISO 88434-1, DIN 2353 or DIN 3861. The EO-2 fittings come in three series: LL, L and S (very light, light, standard/heavy)

The EO-2 is similar to EO – it consists of a body, a progressive ring (ferrule) and a nut – with an addition of elastomeric seal. The elastomeric seal is located between the inner cone of the fitting body and the tube surface, blocking the only possible leak path.

EO-2 fitting bodies are available in over thirty configurations. The shaped products (i.e., elbows, tees, crosses) are hot forged, then machined to the stringent EO-2 fitting specifications. The forging process used by Parker further improves the strength and metallurgical properties of the fitting material.