Basic Equations for Parker Pneumatic Rotary Actuator

Mass Moments of Inertia Equations Table

|

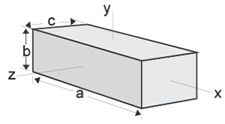

Rectangular Prism Ix = 1/12m(b2 + c2) Iy = 1/12m(c2 + a2) Iz = 1/12m(a2 + b2 ) |

|

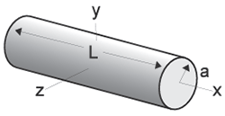

Circular Cylinder Ix = 1/2ma2 Iy = Iz = 1/2m(3a2 + L2)

|

|

|

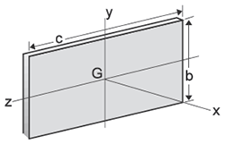

Thin Rectangular Plate Ix = 1/12m(b2 + c2) Iy = 1/12mc2 Iz = 1/12mb2 |

|

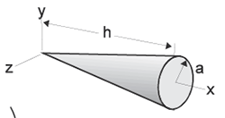

Circular Cone Ix = 3/10ma2 Iy = Iz = 3/5m(1/4a2 + h2)

|

|

|

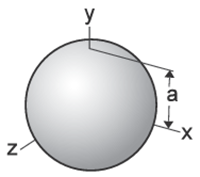

Sphere Ix = Iy = Iz = 2/5ma2 |

|

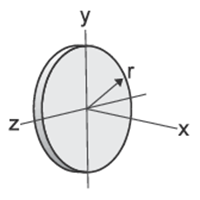

Thin Disk Ix = 1/2mr2 Iy = Iz = 1/4mr2 |

|

|

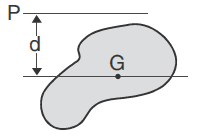

Parallel Axis Theorem Ip = ⌈ + md2

|

|

Ip = Mass moment of inertia about an axis parallel to a centroidal axis ⌈ = Mass moment of inertia about a centroidal axis m = Mass d = Distance between axes |

|

Where:

t = time

θ = angular position

ωt = angular velocity at time = t

ω0 = angular velocity at time = 0

α = angular acceleration

When Acceleration Is Constant:

θ = ω0t + 1/2αt2 ; α = 2θ/t2

θ = ω0t + 1/2ωtt ; α = (ωt - ω0)2/2θ

ω = (ω02 + 2αθ)1/2 ; α = (ωt - ω0)/t

When Velocity Is Constant:

θ = ωt

Basic Velocity, Acceleration, Kinetic Energy and Torque Equations

(The equations below are based on triangular velocity profile.)

Where:

Θ = Angle of rotation (degrees)

t = Time to rotate through Θ (sec)

ω = Angular velocity, radians/sec

α = Angular accelerations (radians/sec2)

WL = Weight of load (lbf)

Ta = Torque to accelerate load (lb-in)

Us = Coefficient of static friction

Jm* = Rotational mass moment of inertia (lb-in-sec2)

Tf = Torque to overcome friction (lb-in)

TL = Torque to overcome effects of gravity

* Use "I" values from the Mass Moments of Inertia table

Equations:

ωmax = 0.35 x Θ/t

α = ωmax2/ (Θ/57.3)

α = ωmax/(t/2)

K.E. = 1/2 Jmω2

Ta = α x Jm

Tf = W x Us x (Distance from pivot point to center of external bearings)

TL = (Torque arm length to C.G. of load) x WL x cos (Φ)

(Where Φ = Angle between torque arm and horizontal plane)

Coefficients of Friction

| Material* | μs | μk |

| Steel on steel | 0.80 | 0.40 |

| Steel on steel (lubricated) | 0.16 | 0.03 |

| Aluminum on steel | 0.45 | 0.30 |

| Copper on steel | 0.22 | 0.22 |

| Brass on steel | 0.35 | 0.19 |

| PTFE on steel | 0.04 | 0.04 |

*Dry contact unless noted

Available Pneumatic Cylinder Styles

|

Tie Rod Cylinders |  |

Guided Cylinders |

|

Round Body Cylinders |  |

Rodless Cylinders |

|

Compact Cylinders |

Engineering & Product Selection Information

Pneumatic Product Selection

- Pneumatic Actuators & Air Cylinders

- Pneumatic Cylinders

- Automation Products: rotary actuators, grippers, slide tables, rotary tables, escapement

- Actuator Accessories: Linear alignment couplers, flow controls, air oil tanks, rodlocks, electronic sensors, shock absorbers

Application Engineering Data

- Operating Principles and Construction

- Fluids and Temperature

- Push and Pull Forces

- Mounting Information

- Ports

- Tie Rod Supports, Stroke Data & Stroke Adjusters

- Mounting Classes

- Stop Tubing

- Stroke Selection Chart

- Deceleration Force and Air Requirements

- Cushion Ratings and Air Requirements

- NFPA Rod End Data and Piston Rods

- Modifications, Special Assemblies, Tandem Cylinders, Duplex Cylinders

- Rotary Actuator Torque Requirements

- Rotary Actuator Basic Equations

- Conversion Factors