Keeping dirt out of your Parker cylinders

Here is a new solution for keeping your 2HD and 3HD Parker cylinders working longer in environments containing abrasive particulates: Parker's new Crown Wiper.

Fine abrasive dust has a way of percolating along the rod through the gland into the cylinder. It ruins seals, causes extra abrasion between the cylinder and piston, and becomes a pollutant in your hydraulic system, wearing down your other hydraulic components as well.

Parker's new Crown Wiper has been proven a superior alternative to piston rod bellows that can ingest particulates and also superior to metallic scrapers that are only effective at cleaning the piston rod.

LEFT: cylinder with standard double-lip wiper installed

LEFT: cylinder with standard double-lip wiper installed

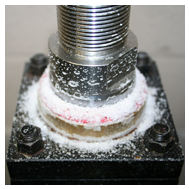

RIGHT: Cylinder with Parker's new Crown Wiper installed

The Crown Wiper has a sharp leading edge to effectively clean the piston rod and a beveled shape to prevent contaminant intrusion by channeling it away from the gland. It also acts as a secondary seal to wipe clean any oil film adhering to the rod on the extended stroke.

It is available in polyurethane material for both Seal Class 1 and 2 seal service and also in fluorocarbon material for Class 5 service in elevated temperature locations.

The Crown Wiper requires a unique gland that is offered as the 2HD & 3HD bolt-on gland design in rod diameters .625" - 5.500", and does not change cylinder mounting dimensions.

Specify a Parker Crown Wiper when ordering Series 2HD or 3HD to protect your cylinder in dirty and abrasive applications.

If you already purchased cylinders without a Crown Wiper, you can still install a gland assembly to retrofit an existing cylinder. Call us with a serial number and we will be able to tell you if your cylinder can be retrofitted.

Parker tells us that they will have Crown Wiper in stock by the end of spring 2010.

Posted by Marek Bobik