Engineering Excellence: How MFCP Transformed a...

A prime example of MFCP taking on complex, high-horsepower projects is when a customer requires...

Parker modular crimpers - choose portable or...

Parker Karrykrimp and Karrykrimp 2 modular crimpers Great improvement in the versatility of the...

Crimping your Parker hose assembly is easy

The Parkrimp system is the easiest way to crimp hose assemblies. The crimp dies are color-coded and...

Preventive maintenance recommendations for Parker...

We all know that preventive maintenance can extend the life of the machinery that we own or...

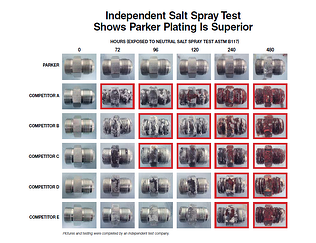

Superior plating results in better corrosion resistance, which in turn prolongs the useful life of a fitting and reduces its overall cost of ownership.

Superior plating results in better corrosion resistance, which in turn prolongs the useful life of a fitting and reduces its overall cost of ownership.