Hose assembly installation tips

Increase your hose assembly service life by avoiding routing mistakes

Here are six quick tips on the correct routing of hose assemblies. They are simple, common sense principles that can prolong your hose's service life and prevent hose failure.

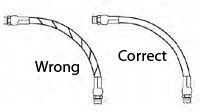

Avoid twisting assemblies

Avoid twisting assemblies

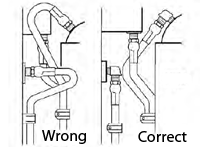

Bending a hydraulic hose assembly in more than one plane causes twisting of its wire reinforcement. A twist of five degrees can reduce the service life of a high-pressure hydraulic hose by as much as 70%. A seven degree twist can result in a 90% reduction in service life.

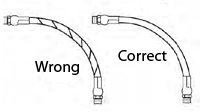

Do not bend hoses tightly

Do not bend hoses tightly

Allow ample bend radius to avoid hose collapse of the line and restriction of flow. Never bend the hose tighter than the minimum bend radius specified by the hose’s manufacturer. Assure that the bend does not start right at the fitting.

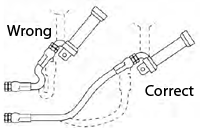

Use elbows or other adapters

Use elbows or other adapters

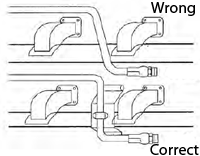

Use elbows or other adapters to ensure the minimum bend radii are within limits specified by the hose’s manufacturer, to reduce needed hose length and to enable hose assemblies to be routed neater – away from harm’s way.

Use hose clamps

Use hose clamps

Using clamps is an important aspect of proper routing. Clamps secure the hose in its proper position and help to keep it from being pulled, hit, crushed or rubbing against surrounding moving parts.

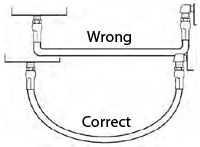

Prevent assemblies from becoming fully extended

Prevent assemblies from becoming fully extended

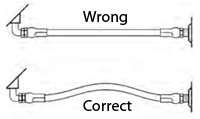

As hose assemblies get pressurized, their diameter increases and they become slightly shorter. If a hose is permitted to assume a fully extended state, it may be too short when pressurized. The result is the hose being pulled out of the fittings. With repeated cycles, this will decrease the hose’s service life and can lead to a failure. Design at least a slight bend/slack to any hose route to prevent this from happening.

Protect assemblies from damage

Hydraulic hose manufacturers estimate that 80% of hose failures are attributable to external physical damage through pulling, kinking, crushing or abrasion of the hose. Abrasion caused by hoses rubbing against each other or surrounding surfaces is the most common type of damage.

To prevent external damage, ensure all clamps are kept secure, pay careful attention to routing whenever a replacement hose is installed and if necessary, use hoses with abrasion resistant cover and/or apply polyethylene spiral wrap to protect hydraulic hoses from abrasion.

Posted by Marek Bobik