Fix your own power steering lines

Fast fix for busted power steering lines - or any tube-hose assemblies

- Get back on the road fast - no delays while replacement assemblies are rushed from the factory.

- Reuse your bent tube ends with hose fittings.

- Replace the hose at a fraction of the cost of a complete assembly.

- You don't need to know how to weld or braze - Ferrul-Fix can be assembled without special tools or equipment when using Parker field-attachable hose fittings.

We all know how long it can take to find a replacement power steering line. Often the dealer has to order it and it can take days to get in. The aftermarket for the power steering lines can also be limited due to rare configurations of the tube part of the assembly specific to each vehicle.

The life of the power steering lines and other combination tube-hose assemblies is usually limited to the service life of the hose alone so you can use Parker Ferrul-Fix to salvage the tube part and attach it to a new hose.

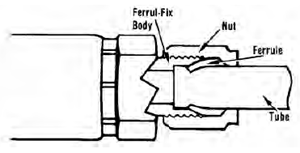

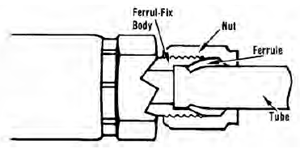

Ferrul-Fix consists of three parts - body, nut and ferrule. The nut pushes the ferrule from the back. The ferrule "bites" into the tube, creating a ridge and forming a seal. Another seal is between the ferrule and the fitting body. The "bite" is visible when the assembly is taken apart providing you a visual confirmation of the seal. The black finish provides "built-in" lubrication which reduces torque required for the assembly.

Ferrul-Fix Installation Instructions

|

|

Posted by Marek Bobik