Busted power steering hose? Save money - salvage your hose ends!

A damaged power steering hose can be frustrating, but buying a whole new hose might not always be necessary. Salvaging and reusing hose ends is a cost-effective solution that many overlook. This guide will walk you through repairing your busted power steering hose, saving you time and money.

Why Salvage Your Power Steering Hose Ends?

Power steering hoses can be expensive to replace, especially if the only problem is a small leak or crack in the hose itself. By salvaging the existing hose ends, you can avoid a complete replacement and keep costs down. Additionally, this method helps minimize waste by reusing functional parts, contributing to a more sustainable repair approach.

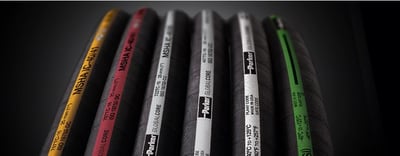

Motion & Flow Control Products, Inc. can repair most of the following automotive hoses:

- Power Steering Hoses: Parker 422, 426, 436 series

- Transmission Hoses and Oil Cooler Hoses: Parker 206 series

- AC Hoses: Parker 285 series and 244 series

Steps for Cost-Effective Power Steering Hose Repair

Follow these steps to salvage your power steering hose ends and replace the hose itself:

- Remove the Damaged Hose: Begin by carefully removing the damaged hose from your power steering system. Use a wrench to loosen and disconnect the hose from the pump and steering gear. Be cautious, as hydraulic systems can retain pressure; relieve any residual pressure before proceeding.

- Inspect the Hose Ends: Once removed, inspect the hose ends for any wear or damage. Reusing hose ends is only viable if they remain in good condition. Look for cracks, corrosion, or other signs of degradation that may compromise their effectiveness.

- Choose the Right Replacement Hose: Select a hydraulic hose compatible with power steering applications. Ensure the replacement hose matches the original's pressure and diameter specifications for safe operation. Look for hoses rated for power steering systems, such as the Parker 422 series, which can handle higher pressure.

- Attach the Hose Ends to the Replacement Hose: Using appropriate hose clamps or fittings, attach the salvaged hose ends to the replacement hose. Make sure to tighten securely to prevent any leaks. If possible, use a hydraulic crimper or consult a specialist to ensure a tight seal.

- Install the Repaired Hose: Reconnect the hose to the power steering system, ensuring all connections are secure. Double-check for leaks by turning the steering wheel and checking for dripping fluid or hissing sounds.

- Refill the Power Steering Fluid: Once installed, refill the power steering fluid reservoir and turn the wheel side-to-side to help remove any air from the system. Regularly check fluid levels and top off as needed to maintain optimal performance.

If you want to learn more, check out the 43-series Ferrul-Fix assembly instructions or 26-series AC tube mender assembly instructions (depending on which hose/fittings combination you are using), or refer to Parker Catalog 4400.

Benefits of Hose End Salvage

- Cost Savings: Salvaging hose ends can cut replacement costs significantly, especially if your power steering hose needs frequent replacement.

- Environmental Impact: Reusing functional parts reduces waste and supports sustainable repair practices.

- Extended Hose Life: By replacing only the damaged section, you’re effectively extending the life of the entire power steering assembly.

Tips for Long-Lasting Power Steering Hose Repairs

To keep your repaired hose in top condition, consider the following maintenance tips:

- Remove the Damaged Hose: Begin by carefully removing the damaged hose from your power steering system. Use a wrench to loosen and disconnect the hose from the pump and steering gear. Be cautious, as hydraulic systems can retain pressure; relieve any residual pressure before proceeding.

- Inspect the Hose Ends: Once removed, inspect the hose ends for any wear or damage. Reusing hose ends is only viable if they remain in good condition. Look for cracks, corrosion, or other signs of degradation that may compromise their effectiveness.

- Choose the Right Replacement Hose: Select a hydraulic hose compatible with power steering applications. Ensure the replacement hose matches the original's pressure and diameter specifications for safe operation. Look for hoses rated for power steering systems, such as the Parker 422 series, which can handle higher pressure.

- Power Steering Hose Repair with Ferrul-Fix: The Ferrul-Fix system is essential for reattaching the salvaged steel hose ends to the new replacement hose. Ferrul-Fix is a 3-piece tube fitting system consisting of a body, nut, and ferrule. Here’s how it works:

- Slide the nut and ferrule onto the end of the hose tube.

- Insert the tube end into the fitting body and screw the parts together.

- As the nut tightens, the ferrule is forced into the fitting body and “bites” into the tube wall, forming a secure seal.

This process effectively reattaches the salvaged steel parts of the power steering hose to the new hose, ensuring a positive seal and reliable connection.

- Install the Repaired Hose: Reconnect the hose to the power steering system, ensuring all connections are secure. Double-check for leaks by turning the steering wheel and checking for dripping fluid or hissing sounds.

- Refill the Power Steering Fluid: Once installed, refill the power steering fluid reservoir and turn the wheel side-to-side to help remove any air from the system. Regularly check fluid levels and top off as needed to maintain optimal performance.

When to Seek Professional Help

While hose salvage is an effective DIY repair, some cases might require a professional. Consult a hydraulic repair specialist if you notice persistent leaks, difficulty steering, or rapid fluid loss. They can ensure your hose meets safety standards and functions optimally under high pressure. You can also save by bringing your power steering hose to any of our stores for repair.

Posted by Marek Bobik | Originally Published September 23, 2011 | Last Updated October 30, 2024