Mechanics might think it is easier to throw down some kitty litter than to really look at a hydraulic leak. Here are two examples of how much a leak can cost you:

Mechanics might think it is easier to throw down some kitty litter than to really look at a hydraulic leak. Here are two examples of how much a leak can cost you:

Example 1:

- Ten simple hydraulic system leaks at the rate of 5 drops/minute add up to 53 gallons of oil lost each year.

- Oil costs from $3 per gallon to more than $30 per gallon.

- Moderately priced oil at $12 per gallon would add up to $636 in lost oil for these leaks, with a potential in the neighborhood of $1,600 over the course of a year.

Example 2:

- A steady stream leak, 1/16 in diameter adds up to 520 gallons of lost oil per year.

- With oil at $12 per gallon, 10 of these leaks would be responsible for up to $62,340 in lost oil alone.

The true cost of a leak however, goes beyond the cost of oil itself. Often times, the so-called "soft cost" associated with the leak can be much more expensive. These costs include:

- Labor and repair expense

- OSHA & EPA fines and litigation expense

- Employee safety expense (lost time accidents)

One answer to the leakage problem is a thought process that includes all facets of the fluid power system design; from concept to first unit prototype. Designers should select proper components in the design. Moreover, all design and engineers should be trained on leakage prevention and troubleshooting techniques.

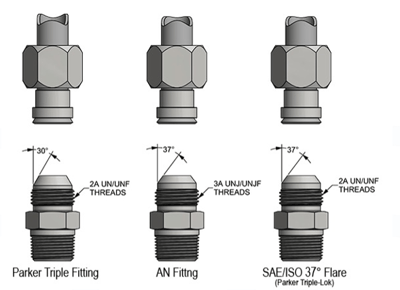

One specific thing to think about to help design a leak-free system is to use o-ring face seal fittings like Parker Seal-Lok in your design instead of JIC fittings.

Posted by Joni Scott

Mechanics might think it is easier to throw down some kitty litter than to really look at a hydraulic leak. Here are two examples of how much a leak can cost you:

Mechanics might think it is easier to throw down some kitty litter than to really look at a hydraulic leak. Here are two examples of how much a leak can cost you: