What Is Causing Your Hydraulic System to Leak?

Did you know that over 100 million gallons of hydraulic fluid are lost each year due to preventable...

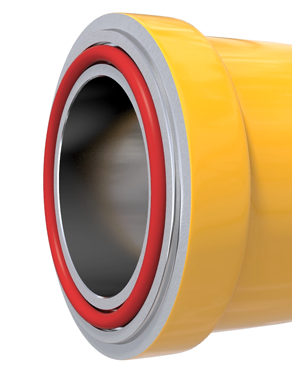

Finding the Right Press in Place (PIP) Seal

We receive many requests regarding seal retention, but why is it so important? There are three main...

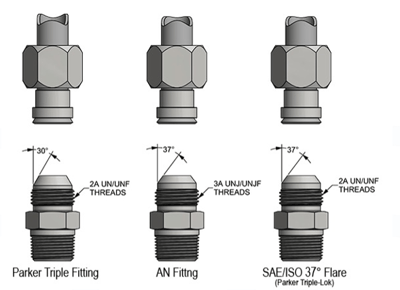

The Differences Between AN and JIC 37° Flare...

When it comes to hydraulic systems and fluid power applications, selecting the right flare fitting...

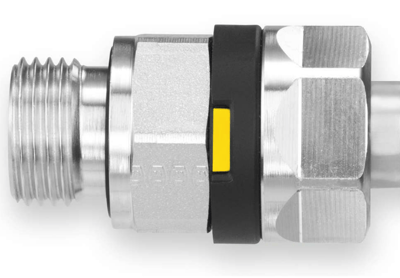

New: Parker's EO-3® Flareless Fitting Visually...

Factors like fluctuating or inexperienced personnel, shortage of skilled workers and increasingly...

Just a quick update - we have added a new technical page on how to correctly assemble Parker Seal-Lok (o-ring face seal) fittings.

Just a quick update - we have added a new technical page on how to correctly assemble Parker Seal-Lok (o-ring face seal) fittings.