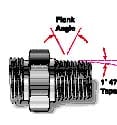

Brake Line Thread Identification Guide: Sizes,...

Understanding brake line thread identification is crucial for ensuring the safety and performance...

How to Identify and Choose the Right Brake Line...

Understanding how to identify and choose the right brake line fittings is crucial for maintaining...

Parker Tracking System at Work

July 8, 2010 - ThyssenKrupp AG (Reno, Nev.) added the Parker Tracking System (PTS) to its annual...