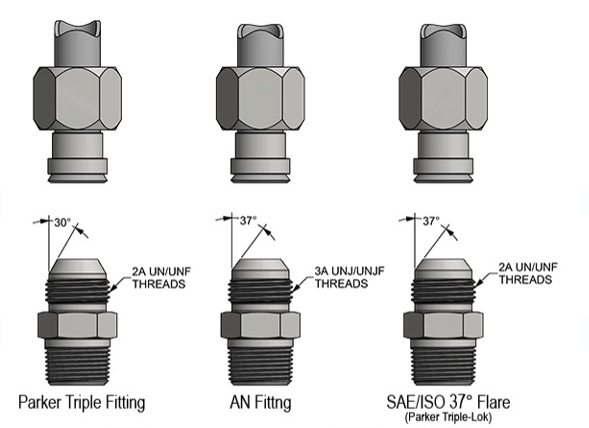

The Differences Between AN and JIC 37° Flare Fittings

When it comes to hydraulic systems and fluid power applications, selecting the right flare fitting is crucial for both performance and safety. Two of the most commonly used types are AN (Army-Navy) and JIC (Joint Industry Council) 37° flare fittings. Though similar, key differences in materials, applications, and design tolerances set them apart. This article explores those distinctions and how to choose the right fitting for your system.

What Are AN 37° Flare Fittings?

AN fittings were originally developed for military and aerospace applications and are designed to meet strict performance requirements. These fittings are known for their ability to withstand high pressure and extreme conditions.

- Materials: AN fittings are typically made from high-quality materials like stainless steel, aluminum, or brass, making them highly durable and corrosion-resistant.

- Applications: AN fittings are commonly used in the aerospace, aviation, and military sectors. They are designed for critical systems where failure is not an option.

- Performance: Thanks to their tight tolerances, AN fittings can handle high-pressure environments, making them ideal for hydraulic systems in demanding industries. For example, the 37° flare fitting is commonly used for its durability and precision in high-performance applications.

What Are JIC 37° Flare Fittings?

JIC fittings, also 37° flare fittings, are commonly used in industrial applications and adhere to standard industrial tolerances. While they share the same 37° flare angle as AN fittings, they differ in design standards and tolerances.

- Materials: JIC fittings are made from carbon steel, stainless steel, or brass, providing a cost-effective option for many industries.

- Applications: JIC fittings are widely used in agricultural equipment, construction, and general hydraulic systems, where the same stringent tolerances as AN fittings are not required.

- Interchangeability: JIC fittings are often interchangeable with AN fittings in non-critical applications, but AN fittings are recommended for high-pressure or high-precision environments.

Key Differences Between AN and JIC 37° Flare Fittings

Although both fittings use a 37° flare angle, there are significant differences between them:

- Manufacturing Tolerances:

AN fittings are manufactured to military specifications with tighter tolerances, making them suitable for high-performance applications. In contrast, JIC fittings have looser tolerances, making them more affordable for general industrial use. - Material and Durability:

AN fittings, made from more durable materials like stainless steel or aluminum, offer greater resistance to corrosion and wear. JIC fittings are available in carbon steel, which is sufficient for less demanding applications but may not offer the same level of longevity in harsh environments. - Applications:

AN fittings are used in critical applications such as aerospace, military, and high-pressure hydraulic systems, while JIC fittings are commonly found in agriculture, construction, and industrial systems where high precision isn’t as critical. - Cost:

The higher manufacturing standards of AN fittings come at a premium price. JIC fittings are a cost-effective alternative for less demanding environments, making them the more common choice for industrial applications.

Choosing the Right Fitting for Your Application

When deciding between AN and JIC 37° flare fittings, consider the following:

- Pressure Ratings:

AN fittings offer superior performance for systems that operate at high pressures due to their tighter tolerances and higher-quality materials. Learn more about hydraulic fittings for high-pressure systems to find the best options for your application. - Corrosion Resistance:

If your system is exposed to harsh environmental conditions or corrosive fluids, AN fittings made from stainless steel or aluminum may provide the necessary durability. - Budget:

For general hydraulic systems that don’t require extreme precision or high-pressure handling, JIC fittings offer a cost-effective solution without compromising safety.

Frequently Asked Questions (FAQs)

- Can AN and JIC fittings be used interchangeably?

Yes, AN and JIC fittings can be used interchangeably in many non-critical applications. However, AN fittings are recommended for high-pressure or high-precision environments. - What materials are used to manufacture AN and JIC fittings?

AN fittings are typically made from high-quality materials like stainless steel, aluminum, or brass, while JIC fittings are made from carbon steel, stainless steel, or brass. - Are there specific standards AN and JIC fittings must meet?

Yes, AN fittings conform to SAE J514 and ISO 8434-2 standards, ensuring high performance in critical applications. JIC fittings also follow SAE J514 but are designed for broader industrial use.

Understanding the differences between AN and JIC 37° flare fittings is essential when selecting the right component for your hydraulic or fluid power system. AN fittings provide superior performance for high-pressure and high-precision applications, while JIC fittings offer a more affordable solution for general industrial use. To learn more or explore our range of fittings, contact MFCP today.

For more technical insights into the differences between AN and JIC 37° flare fittings, see this external resource.