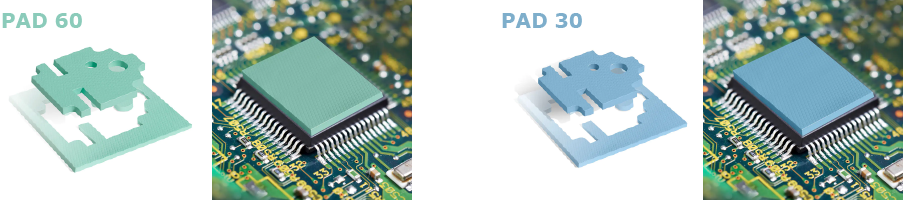

New: PAD60 & PAD30 Thermal Gap Fillers from Parker Chomerics

PAD 60

PAD 60 is a 6.0 W/m-K next-generation high-performance gap filler. The high conductivity combined with extreme softness (31 Shore 00 durometer) and surface tack result in very low thermal impedance values in electronics applications. Uniquely, PAD60 features mechanical elasticity which aids in vibration dampening, reliability, and system architecture requiring cyclical accessibility. Applications such as smart home devices, SSDs, CPUs, power supplies, power amplifiers, telecom devices, and automotive electronic control modules, among many others, are well suited to the performance properties of PAD60.

PAD 30

PAD30 is a 3.2 W/m-K gap filler that is very attractively priced for a wide variety of applications. This ultra-soft material (38 Shore 00 durometer) conforms easily to surface irregularities and mitigates high dimensional tolerances. A workhorse mid-range performer, PAD30 is an economical solution, price competitive in even the highest volume consumer electronics products. PAD30 can be offered in an unstructured, natural tack form, as well as with PSA, a glass fiber carrier substrate, or on dielectric film carriers (polyimide or PEN).

MFCP

MFCP is the largest full-line Parker Hannifin distributor in the United States and an authorized Parker Chomerics distributor and fabricator of thermal pads, EMI gaskets, and vulcanized seals, along with non-conductive seals and gaskets. MFCP can provide both bulk sheets as well as converted geometries to customer specifications. Look to MFCP for applications engineering assistance and the best in the industry lead times & product support.