Parker Metal PLP & PrestoWeld Fittings Update

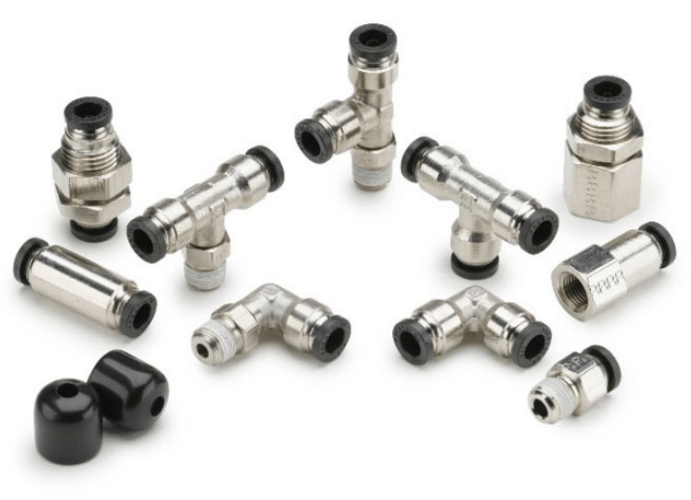

Unfortunately, we are all getting used to product changes necessitated by disruption in the supply chain. Plastic parts, seals, adhesives, and metal plating (to name a few) are changing chemical composition to deal with shortages of chemicals and metals. But this time, Parker’s Fluid System Connectors Division product changes come with some benefits.

PLP Push-Button-Change

Fluid System Connectors Division announced a material and color change to their current Inch PLP Metal release buttons. The PLP fitting release buttons are changing color from green to black and will now be manufactured from PVDF (Kynar®) instead of polyacetal.

The good news is that PDVF has a better UV and chemical compatibility than polyacetal and that the whole line of PLP fittings now has a consistent look. In addition, PVDF meets the UL94 V-0 flame resistance standard required for welding applications.

Product boxes with manufacturing date codes starting with 01/03/2022 (see example below) will have the new black PVDF release buttons. Please remind your team to use FIFO inventory replenishment to help prevent possible product mixing.

PrestoWeld Fittings Discontinued

In conjunction with Parker’s upgrade of PLP fittings to UL94 V-0 flame resistance standard, Parker’s Fluid Systems Connector Division announced the discontinuance of the PrestoWeld PW Series push-to-connect weld fittings. The PrestoWeld fittings are replaced with the PLP Metal fittings offering. The collar material was the only difference between the PrestoWeld and metal PLP fittings, so the new PLP is in fact exactly the same as PrestoWeld. Since both products have an exact form, fit, and function, it makes no sense to have two part numbers.

PrestoWeld to PLP Cross-Reference

| for 164PW‐4 | use 164PLP‐4 |

| for 164PW‐6 | use 164PLP‐6 |

| for 164PW‐8 | use 164PLP‐8 |

| for 165PW‐4 | use 165PLP‐4 |

| for 165PW‐6 | use 165PLP‐6 |

| for 165PW‐8 | use 165PLP‐8 |

| for 62PW‐4 | use 62PLP‐4 |

| for 62PW‐6 | use 62PLP‐6 |

| for 62PW‐8 | use 62PLP‐8 |

| for 62PWBH‐4 | use 62PLPBH‐4 |

| for 62PWBH‐6 | use 62PLPBH‐6 |

| for 62PWBH‐8 | use 62PLPBH‐8 |

| for 66PW‐4‐4 | use 66PLP‐4‐4 |

| for 66PW‐6‐4 | use 66PLP‐6‐4 |

| for 66PW‐6‐6 | use 66PLP‐6‐6 |

| for 66PWBH‐4‐4 | use 66PLPBH‐4‐4 |

| for 66PWBH‐6‐6 | use 66PLPBH‐6‐6 |

| for 66PWBH‐8‐6 | use 66PLPBH‐8‐6 |

| for W169PW‐4‐2 | use W169PLP‐4‐2 |

| for W169PW‐4‐4 | use W169PLP‐4‐4 |

| for W169PW‐4‐6 | use W169PLP‐4‐6 |

| for W169PW‐6‐4 | use W169PLP‐6‐4 |

| for W169PW‐6‐6 | use W169PLP‐6‐6 |

| for W169PW‐6‐8 | use W169PLP‐6‐8 |

| for W169PW‐8‐4 | use W169PLP‐8‐4 |

| for W169PW‐8‐6 | use W169PLP‐8‐6 |

| for W169PW‐8‐8 | use W169PLP‐8‐8 |

| for W171PW‐4‐2 | use W171PLP‐4‐2 |

| for W171PW‐4‐4 | use W171PLP‐4‐4 |

| for W171PW‐4‐6 | use W171PLP‐4‐6 |

| for W171PW‐6‐4 | use W171PLP‐6‐4 |

| for W171PW‐6‐6 | use W171PLP‐6‐6 |

| for W171PW‐8‐6 | use W171PLP‐8‐6 |

| for W171PW‐8‐8 | use W171PLP‐8‐8 |

| for W172PW‐4‐2 | use W172PLP‐4‐2 |

| for W172PW‐4‐4 | use W172PLP‐4‐4 |

| for W172PW‐4‐6 | use W172PLP‐4‐6 |

| for W172PW‐6‐4 | use W172PLP‐6‐4 |

| for W172PW‐6‐6 | use W172PLP‐6‐6 |

| for W172PW‐6‐8 | use W172PLP‐6‐8 |

| for W172PW‐8‐4 | use W172PLP‐8‐4 |

| for W172PW‐8‐6 | use W172PLP‐8‐6 |

| for W172PW‐8‐8 | use W172PLP‐8‐8 |

| for W68PW‐4‐2 | use W68PLP‐4‐2 |

| for W68PW‐4‐4 | use W68PLP‐4‐4 |

| for W68PW‐4‐6 | use W68PLP‐4‐6 |

| for W68PW‐6‐4 | use W68PLP‐6‐4 |

| for W68PW‐6‐6 | use W68PLP‐6‐6 |

| for W68PW‐6‐8 | use W68PLP‐6‐8 |

| for W68PW‐8‐4 | use W68PLP‐8‐4 |

| for W68PW‐8‐6 | use W68PLP‐8‐6 |

| for W68PW‐8‐8 | use W68PLP‐8‐8 |