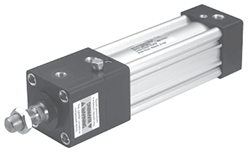

Parker P1D Cylinders Improve Pneumatic System Safety [During Power Outage]

![Parker P1D Cylinders Improve Pneumatic System Safety [During Power Outage]](https://www.mfcp.com/hs-fs/hubfs/images/product/Pneumatic-Actuator-Products/Tie-Rod-Pneumatic-Cylinders/parker-P1D-series-rod-lock.png?height=500&name=parker-P1D-series-rod-lock.png)

In many automated manufacturing applications, assessing potential safety risks posed by unexpected power failure is an essential part of overall system design. You need to take appropriate measures in order to reduce the risk of injury to machinery operators and other personnel, and prevent damage to the products being assembled. In the case of any kind of unexpected interruption in operation, the equipment must meet safety standards that prevent unsafe situations from occurring.

One of the most common causes of a system stop is a power outage or a major breach/leakage in the supply line. In pneumatic systems the loss of power is typically associated with loss of air supply or significant drop in the air pressure.

Whatever the reason, the pneumatic system needs to be designed to address the situation so that a load does not drop unexpectedly, or does not get ejected or knocked off production line because some cylinders are out of synchronization.

One solution to controlling pneumatic cylinders during unexpected loss of air pressure is the utilization of rod locking cylinders.

Rod locking cylinders, such as Parker's ISO standard P1D series cylinders, have been designed to hold loads safely in position in case of pressure drop. The rod locking feature is a mechanical function provided by a cartridge through which the piston rod passes. It is mounted transversally in the rod lock unit of the cylinder.

Use rod locking cylinders wherever an unexpected loss of air pressure could result in cylinder movement that can cause damage to machinery or injuries to nearby personnel.

The rod locking cylinders require signal pressure in order to be operational. When air supply is lost, the drop in pressure causes a loss of signal pressure and the force from a set of internal springs pushes the jaw clamps to lock the piston. Once the pressure is restored to the system, the pressure in the signal port overcomes the force of the springs and the cylinder becomes operational again.

Please note that rod locking cylinders can only be used in dry piston rod applications. Any grease, lubricants or coolants will reduce the lock’s effectiveness. Parker's rod locking cylinders use air / spring activation mechanism which is fully integrated into the cylinder design, saving space and simplifying installation.

Parker supplies two basic types of rod locking cylinders:

- P1D-L for dynamic applications

- P1D-H for static designs

Both types of pneumatic cylinders can hold the piston at any point in its stroke.

Dynamic Applications of Rod Locking Cylinders

Some rod locking pneumatic cylinders may be used for dynamic applications where they can act as a brake by engaging while the rod is moving.

Operation is achieved by the axial movement of a piston; with no signal pressure a number of high force springs force the piston to move axially. The movement is applied to the cylinder via the conically shaped inner ring of the piston. This is then converted into radial movement of clamping sleeves using hundreds of high precision steel balls, resulting in the hardened sleeves being pressed onto the piston rod with a high, stable holding force.

The surface of the clamping sleeves that are applied to the piston rod have a special design with a pattern of grooves that provide maximum grip. This design feature improves the holding capabilities of the cylinder significantly – especially in applications where there is a risk that the piston rod will be exposed to oil, grease, dirt or other contaminants.

Static Applications of Rod Locking Cylinders

In static applications – where piston rod locking only takes place when there is no piston movement of the piston and no pressure signal – the rod lock unit is usually externally flange-mounted on the front end of the cylinder body.

The locking force is provided by the cartridge which is mounted transversally in the rod lock unit. The piston rod passes through the cartridge and when there is no signal pressure, the force from the internal springs pushes the over-the-center mechanism to lock the piston with the jaws clamping onto the piston rod and holding the cylinder firmly and safely in position.

In the case of the static rod locking cylinder, designers need to be aware that the sharp edge of the jaws will be damaged if the piston rod is not stationary before the rod lock unit is engaged.

It is important to note that rod locking cylinders should not be used as the only safety component in an application; they are designed for emergency use. Other technologies should be used to achieve planned braking or holding.

Learn more about rod-lock cylinders on our pneumatic cylinder product pages.

(This blog is adapted from an article written by Franck Roussillon, EMEA product manager - Automation Actuators, Pneumatic Division Europe, Parker Hannifin Corporation)