Hydraulic Fitting Selection – Differences Among Attachment Styles

We get a few requests per month for a standard fitting. In the world of fittings, there isn’t any that can be called “standard” or “typical.” When trying to determine which fitting type is going to get your machine moving again, there are several different options available. The goal in this piece of information is to help you better understand those options. What follows is information that pertains to how fittings are attached to either a Hydraulic Hose or to a Hardline (Steel or Stainless Steel) Tube. Knowing the fitting type needed before attempting to procure it can save you time, which as we all know equates to $$$.

1) Hydraulic Hose Crimp Fitting: Using crimp fittings requires a crimping machine or a press to attach the fitting to the hose. If you don’t have a machine of this type in your shop or facility, a local Hydraulic Distributor or Supplier can fabricate the hose assembly.

1) Hydraulic Hose Crimp Fitting: Using crimp fittings requires a crimping machine or a press to attach the fitting to the hose. If you don’t have a machine of this type in your shop or facility, a local Hydraulic Distributor or Supplier can fabricate the hose assembly.

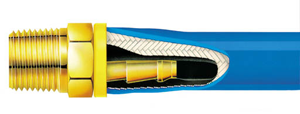

2) Hydraulic Hose Field Attachable Fitting: The advantage of field attachable fittings (also referred to as Reusable Fittings) is that a machine isn’t required to attach the fitting to the hose. The hose assembly can be made anywhere provided that the fitting and the hose on hand is  compatible. In most cases, a Field Attachable Fitting consists of two pieces; a socket and a nipple. Depending on the exact type of fitting used, assembly instructions will vary.

compatible. In most cases, a Field Attachable Fitting consists of two pieces; a socket and a nipple. Depending on the exact type of fitting used, assembly instructions will vary.

The two types of Hydraulic Hose Fittings above are used on a pressure line of the machine. There is another type of hose fitting that is designed to be used on the lower pressure part of the machine or system. These lower pressure lines are known as Suction or Return lines and utilize barbed fittings.

3) Field Attachable Barbed Fitting: This fitting consists of a one piece barbed fitting that after being inserted into the hose is secured with a worm clamp or double bolt clamp. This fitting is used in a low pressure hydraulic application such as a suction line or return line.

3) Field Attachable Barbed Fitting: This fitting consists of a one piece barbed fitting that after being inserted into the hose is secured with a worm clamp or double bolt clamp. This fitting is used in a low pressure hydraulic application such as a suction line or return line.

Parker also makes a barb fitting called Push-Lok that does not need a clamp if used with Parker Push-Lok hose.

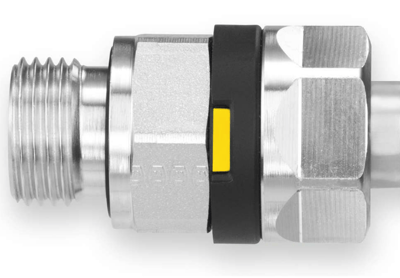

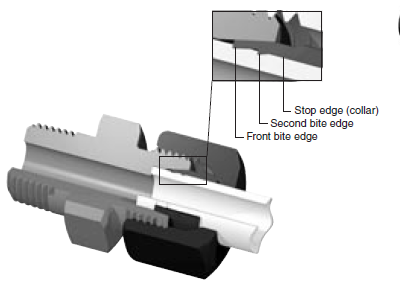

4) Compression Fitting for Steel Tube: Compression fittings use a metal ring (the compression ring) which is squeezed onto the pipe and into the fitting by a compression nut. The soft metal conforms to the surface of the steel tube and the fitting and creates a seal. The advantage to this type of tube fitting is that it can be attached to the tube in a field application without the aid of machinery.

4) Compression Fitting for Steel Tube: Compression fittings use a metal ring (the compression ring) which is squeezed onto the pipe and into the fitting by a compression nut. The soft metal conforms to the surface of the steel tube and the fitting and creates a seal. The advantage to this type of tube fitting is that it can be attached to the tube in a field application without the aid of machinery.

Posted by Roger Winchell