What Type of Pipe Should I Use for My Air Compressor?

Table of Contents

When it comes to what kind of pipe to use for air compressor lines, one of the most important things to understand is that not all of your options are created equally. Much of your decision will be made based on the specific type of project you're working on, along with the precise goals you're trying to achieve with your air compressor.

1. PVC Pipe

The use of PVC pipe for air compressor lines is common, but is ultimately NOT RECOMMENDED for use in this context. Air compressor PVC pipe is often used because it is readily available, inexpensive, and easy to install. However, as with many plastics, PVC air line material gets brittle over time and can crack, break, or even shatter. The presence of air compressor oils in the line and heat from the compressed air accelerates the degradation of PVC for air lines. These failures, combined with air under pressure, are potentially fatal due to the airborne, razor-sharp shrapnel. It is also an OSHA violation to use PVC for compressed air distribution, which means you could incur a hefty fine. In other words, the answer to the question, "Can you use PVC for air lines?" is a resounding, "No."

2. Galvanized Pipe

Galvanized piping is commonly used for water distribution and for general plumbing. Galvanized coating resists moisture in compressed air, but pieces of the coating will flake off and end up in your tools. The debris will cause severe damage to cylinders, pneumatic tools, and other components. Even more importantly, when exiting a blow gun, little flakes can cause serious bodily harm. As was true with PVC pipe for compressed air and related uses, galvanized piping is NOT RECOMMENDED for compressed air systems.

3. Black Pipe

Black pipe is the most commonly used pipe RECOMMENDED for compressed air systems. It is readily available, negating one of the major benefits that people think that PVC air line options have to offer. Not only that, but it is strong and durable and most people are familiar with how to install it. With all the advantages black pipe provides, however, it will produce rust contamination that damages pneumatic tooling. The pipe is uncoated, and the presence of moisture will initiate rusting, which will increase over time. The presence of moisture can be controlled with an after cooler and/or dryer, but it can never be completely eliminated. Furthermore, the installation of black pipe systems requires a significant amount of time. Plan carefully, changes to the system will require de-pressurizing the system while new drops or additional loops are added. So can you use black pipe in this context? Yes. Is it the absolute best option? Not necessarily.

4. Copper Pipe

Copper pipe is commonly RECOMMENDED for clean air. It works very well, although some have been known to balk at the fact that it is expensive. Copper pipe makes for an aesthetically pleasing installation, but the soldering of joints is time-consuming and requires skill. It's a high quality solution, but it won't necessarily be a quick or inexpensive one. You can rest easy knowing that since the combination of copper and water does not create any corrosion or rusting, the air delivered to the pneumatic tools is clean and free of particulates.

5. Stainless Steel

The RECOMMENDED use of stainless steel to minimize corrosion has a long and successful history. When most people think about using PVC pipe for air compressor lines, the benefits they typically call to mind are ones that are actually offered by stainless steel. It also combines all the strength and durability benefits of black pipe, but without the problem of rusting. As with black pipe, most people are familiar with how to install the fittings and pipe, but the installation is a lengthy process. Stainless steel pipe threads also have a tendency to gall and freeze up, which can cause great difficulty during disassembly, and for general maintenance. For this reason, Victaulic fittings have successfully been used. Victaulic fittings are installed with a rubber seal and bolted clamp. Victaulic fittings are the preferred fittings for larger pipes, whether black or stainless steel, due to their lighter weight.

6. Aluminum Pipe

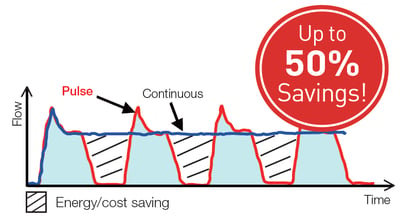

The latest technology is push-to-connect aluminum piping systems for compressed air lines (such as Parker Transair). Aluminum is a light-weight option, making it easy to handle compared to schedule 40 or 80 pipe, and is HIGHLY RECOMMENDED for clean air applications. It is non-corrosive, and remains leak free, unlike black pipe systems. Considering the high cost of producing compressed air, reducing compressed air consumption by eliminating leaks over the life of the system is a major benefit of using Parker Transair. Skilled labor is not required to install TransAir.

Parker cites the following benefits of its Transair piping:

- Fast installation. There is no welding, soldering or other time-consuming methods of attachment. All you must do is push the pipe into a fitting until it bottoms out.

- Light-weight. The product is very easy to handle.

- Non-corrosive. It provides clean air for years to come, prolonging the working life of components in the system.

- Very adaptable. It is easy and fast to change (reroute) or add new components and drops, even under pressure.

- The overall higher up-front cost of materials (compared to black pipe) may discourage some from exploring this option, but the difference in cost of material is recovered by savings on labor during (typical) installation (parts are no good when they’re sitting in a pile on the floor).

- Most likely the lowest cost of ownership compared to the other types of piping, especially if changes to the system configuration are required.

In the end, there are many choices when it comes to piping for your compressed air system. Do not use PVC or galvanized pipe. If anyone ever asks, "Can I use PVC for air compressor lines?" be sure to tell them, "No."

If you can help it, it’s always best to steer clear of black pipe as well – you will save time, money, and headaches by avoiding these options.

Instead, you should choose among these suitable options — copper piping, stainless steel piping and aluminum piping. Based on the requirements of your application, the skills of your staff, and time constraints, the best solution will quickly become clear. If you think that additions or changes to your system(s) are likely, go with a push-to-connect aluminum piping system such as Transair.

This article was originally published on August 28, 2013, and was last updated on June 6, 2024.