Maintenance

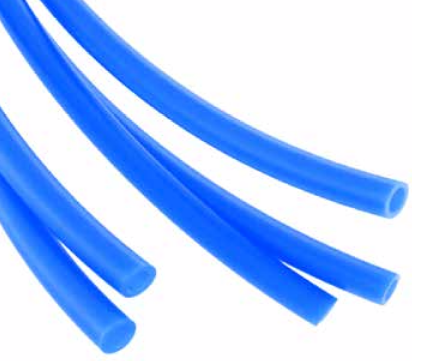

Sanitized Treatment Helping Control Microbial...

This tubing is specially formulated with Sanitized® to resist degradation from mildew, algae, fungi...

Read More

Fisher Snow Plows Move Snow – Fast

Beat the Weather Every Time With Fisher Snowplows We're Fisher fans because they like what we like:...

Read More

Winter is Coming - Get Fisher Snowplows at MFCP

Autumn leaves may have just started to fall, but snowy days will be here before you know it. At...

Read More

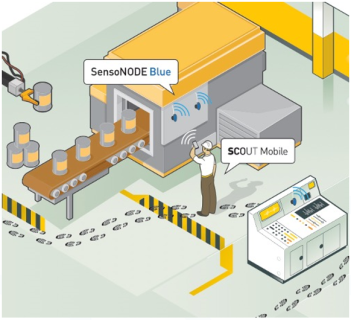

Preventive Maintenance vs. Predictive Maintenance

Author: Dan Davis, product sales manager, Parker Hannifin. The terms Preventive maintenance and...

Read More

Our Bay Area, California Stores are Operated by...

Our Bay Area, California stores (in San Leandro and Fremont) are open but only staffed with...

Read More

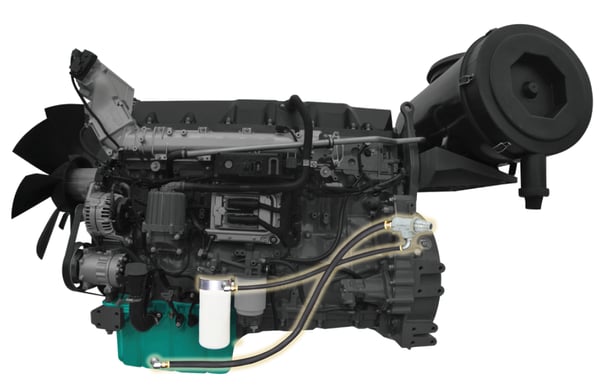

Quicker, Cleaner, Safer Oil Change for Heavy...

Parker’s QuickFitTM System facilitates a quicker, cleaner and safer oil change process for truck,...

Read More

OSHA Is Considering Changes to their Respirable...

OSHA Requests Input on Proposed Changes to the Silica Standard OSHA sent a Trade Release out on...

Read More

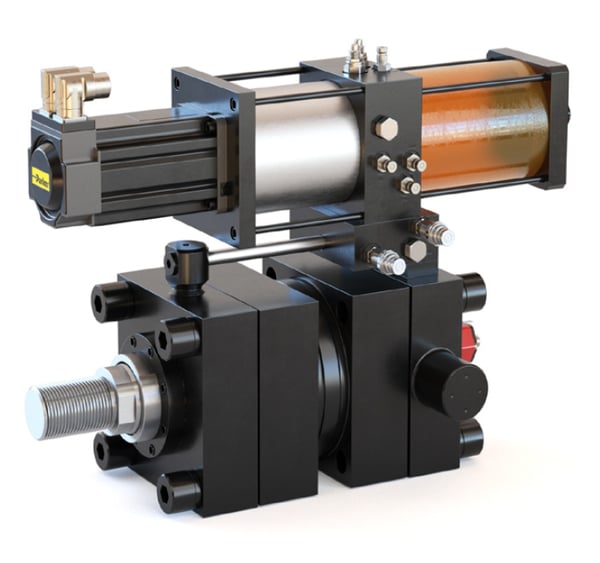

Comparison of Alternative Actuating Systems:...

Electromechanical (EM) actuating systems have been increasing in popularity for some time. They...

Read More

Save Your Workers' Lungs & OSHA's Staggering...

Last year, we wrote about OSHA's new enforcement focus on violations of crystalline silica rule,...

Read More

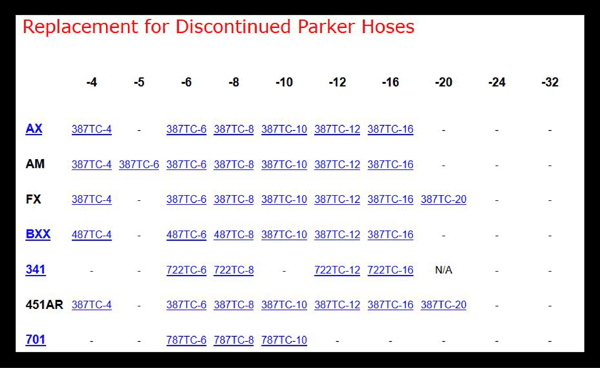

If you Use Parker Hydraulic Hoses, Read This

Parker will discontinue 30 of its legacy hoses by next June. Of those 30 hoses 22 will become...

Read More

Making and re-making flange connections? Use...

If you are repairing or maintaining hydraulic equipment, you make and re-make connections daily....

Read More

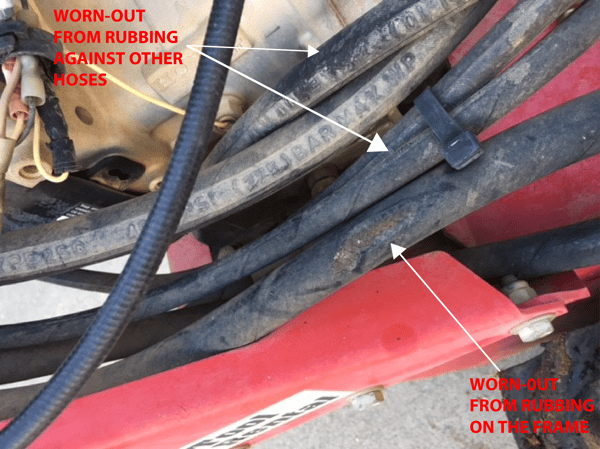

Renters of Hydraulic Equipment May Be Exposed to...

We have written several blogs in the past about risks associated with using equipment with worn-out...

Read More

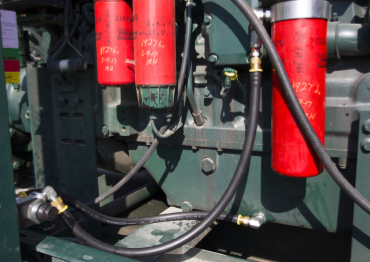

Oil Change In Under 30 Minutes with the Parker...

Depending on your equipment, an oil change can be a complicated, potentially messy process. It is...

Read More

The Mechanic's Secret Weapon: Free-All Loosens...

Let’s face it – rust happens. Whether it’s equipment that has been exposed to the elements over...

Read More

Finally - An Industrial Hand Cleaner That Won't...

When it comes to cleaning up after working with paint, oil, grease, tar and other types of tough...

Read More

Avoid Safety Violations | Comply with OSHA's New...

Parker 7084 Series Twinhammer hose conveys both air to power the jackhammer and water to spray down...

Read More

Which is the Best Way to Protect Hydraulic Hoses...

According to Fluid Power Journal article, "Industry and user experience agree 70% of [hydraulic...

Read More

NEW: Seals for High Temperature Applications

If your hydraulic equipment is exposed to spikes of high temperatures, industry standard...

Read More

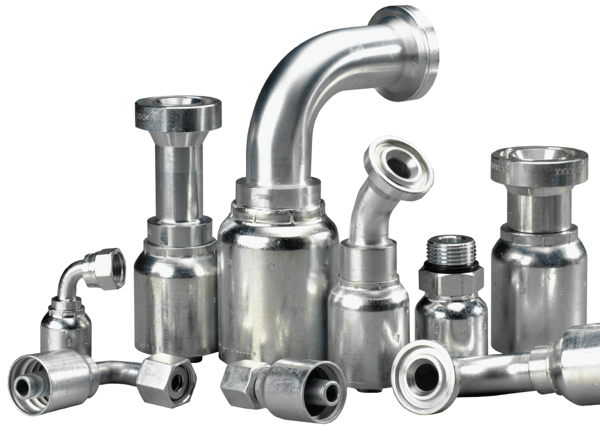

Parker 77 Series Crimp Fittings Now Available in...

In a previous blog, we wrote about the GlobalCore series of hose from Parker, which can streamline...

Read More

Converting Parker Legacy 2H/3H Hydraulic...

Last year, Parker introduced the Gen II style hydraulic cylinders, which replace the legacy 2H and...

Read More

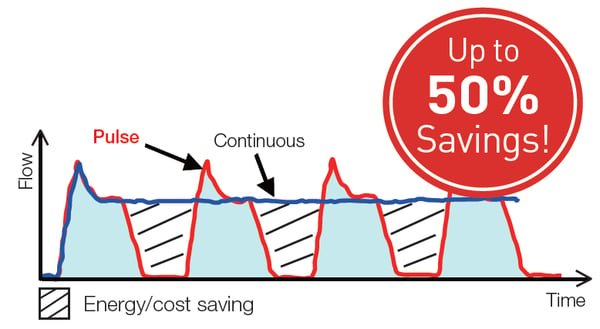

Reducing Compressed Air Consumption in Blow...

Anyone running a pneumatic system knows that producing compressed air requires a lot of energy. In...

Read More